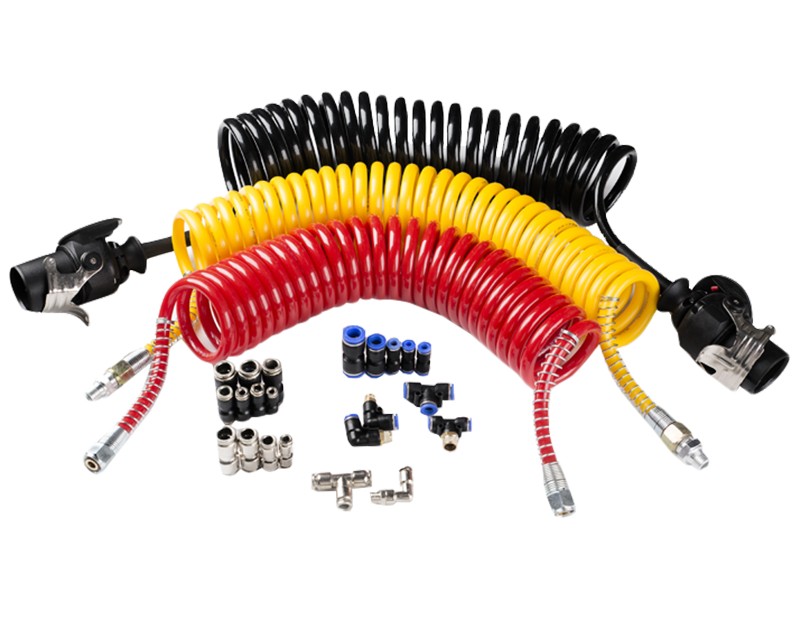

Regular maintenance of trailer air hoses is crucial to avoid costly downtime and ensure the safety and efficiency of the trailer's braking system. Air hoses play a vital role in transmitting air pressure from the tractor to the trailer's brake system, and any damage or malfunction can lead to brake failure and potential accidents. Here are some essential tips for regular maintenance of trailer air hoses:

Visual Inspection: Perform regular visual inspections of the air hoses to check for signs of wear, damage, or leaks. Look for cracks, abrasions, kinks, or bulges in the hoses. Additionally, inspect the fittings and connectors for signs of corrosion or loose connections.

Replace Damaged Hoses: If you notice any signs of damage or wear during the visual inspection, replace the damaged hoses immediately. Do not attempt to repair them, as compromised hoses can lead to air leaks and brake failure.

Check for Proper Sealing: Ensure that all connections and fittings are properly sealed to prevent air leaks. Even minor air leaks can significantly affect the brake system's performance and result in decreased braking efficiency.

Keep Hoses Clear of Obstructions: Make sure that the air hoses are clear of any obstructions or debris that could cause damage or restrict the airflow. Avoid placing heavy objects on the hoses or running them along sharp edges.

Protect Hoses from Extreme Temperatures: Exposure to extreme temperatures can cause the hoses to degrade faster. Whenever possible, park the trailer in a shaded area or use protective covers to shield the hoses from direct sunlight and extreme heat or cold.

Follow Manufacturer's Recommendations: Adhere to the manufacturer's recommendations for maintenance intervals and replacement schedules for the air hoses. Regularly replace hoses as recommended to ensure optimal performance.

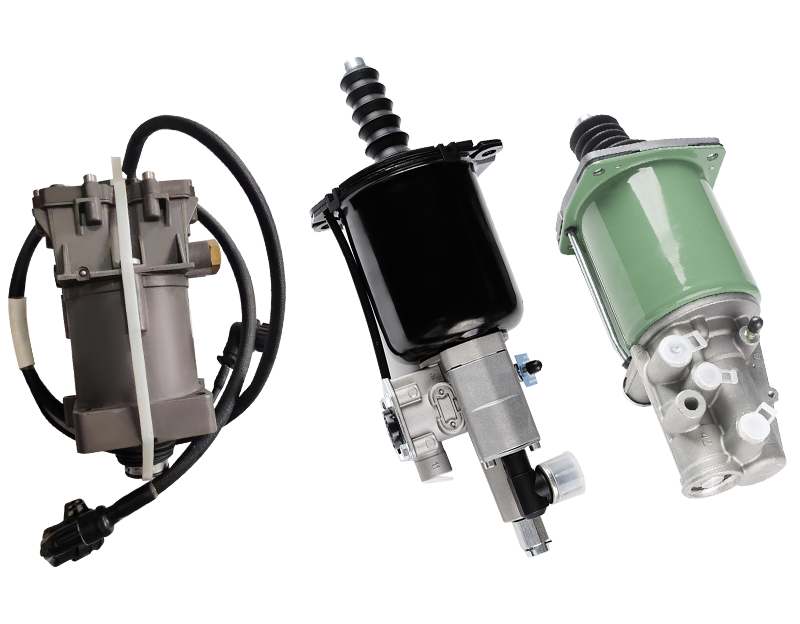

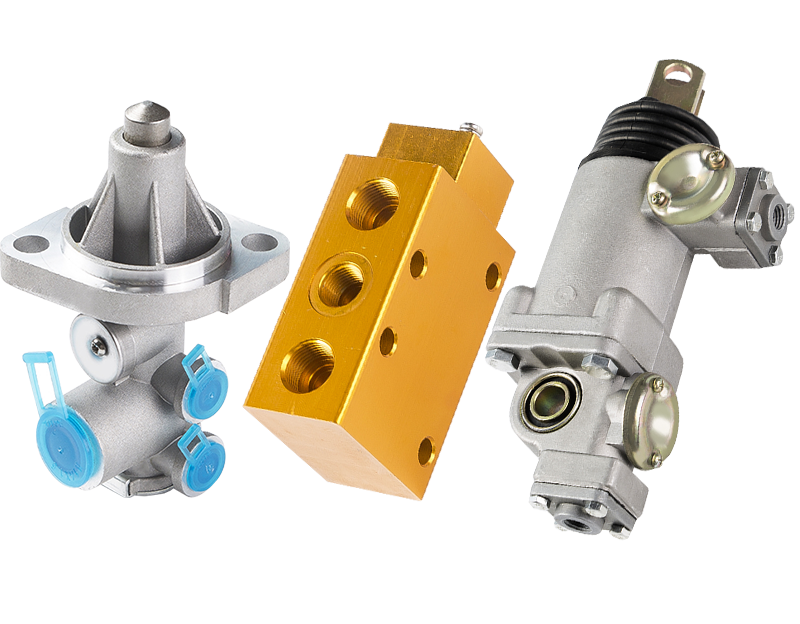

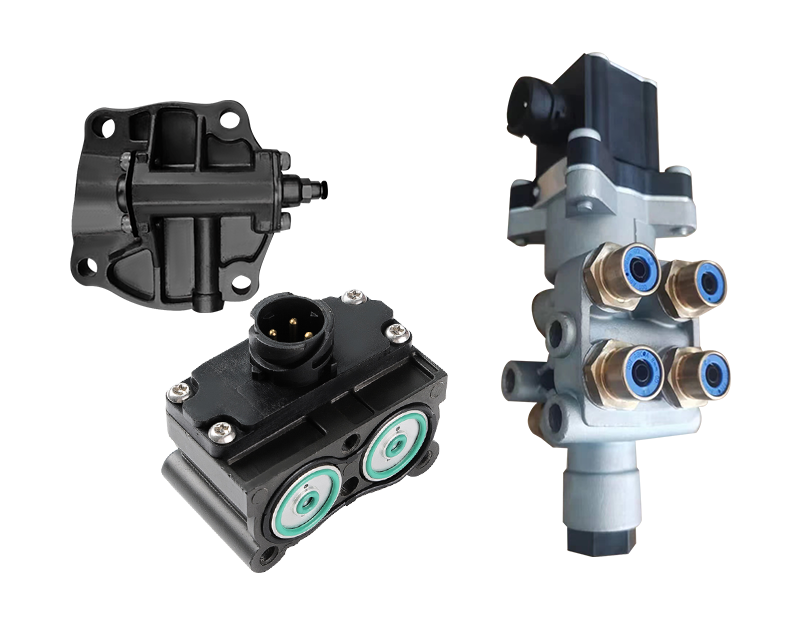

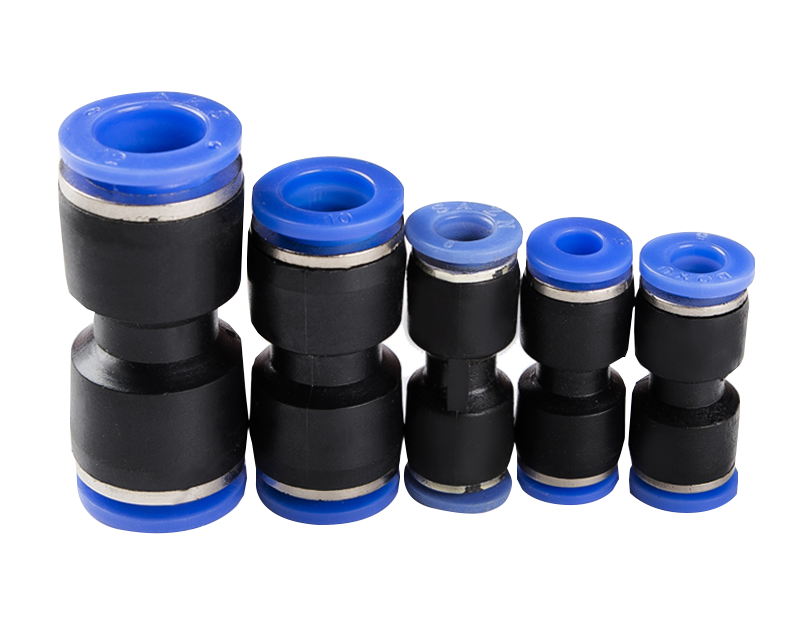

Use Quality Air Hoses and Fittings: Invest in high-quality air hoses and fittings that are designed to withstand the rigors of commercial trailer use. Quality components are more durable and less likely to fail prematurely.

Train and Educate Drivers: Train drivers on proper handling and care of the trailer's air hoses. Make sure they are aware of the importance of regular inspections and reporting any issues they notice during pre-trip checks.

Maintain a Record of Maintenance: Keep a detailed record of all maintenance performed on the trailer's air hoses. This record will help you track the maintenance schedule and identify any recurring issues that may require attention.

Perform Brake System Tests: Regularly conduct brake system tests to ensure that the air hoses are functioning correctly and the brake system is operating within acceptable parameters. If any issues are detected during the tests, address them promptly.

By following these tips for regular maintenance of trailer air hoses, you can minimize the risk of costly downtime due to brake system failures and ensure the safety and efficiency of your trailer operations. Regular maintenance not only prevents unexpected breakdowns but also extends the lifespan of the air hoses, saving you money in the long run. Taking proactive measures to care for your trailer's air hoses will contribute to safer and smoother transportation operations, giving you peace of mind on the road.

English

English Español

Español