In the world of industrial machinery and automation, pneumatic fittings might appear inconspicuous, but they are essential components that bridge the gap between air compression and motion control. These connectors, designed to facilitate the flow of air or gas, play a pivotal role in ensuring the efficient operation of pneumatic systems. This article delves into the realm of pneumatic fittings, exploring their diverse types and applications across various industries.

Understanding Pneumatic Fittings

Pneumatic fittings serve as the linchpin in the assembly of pneumatic systems. Their fundamental purpose is to create secure and airtight connections between different sections of pneumatic tubing or hoses. These fittings are engineered to withstand the elevated pressures common in pneumatic systems, ensuring the overall system's integrity and reliability.

Types of Pneumatic Fittings

Pneumatic fittings come in various types, each tailored to specific applications:

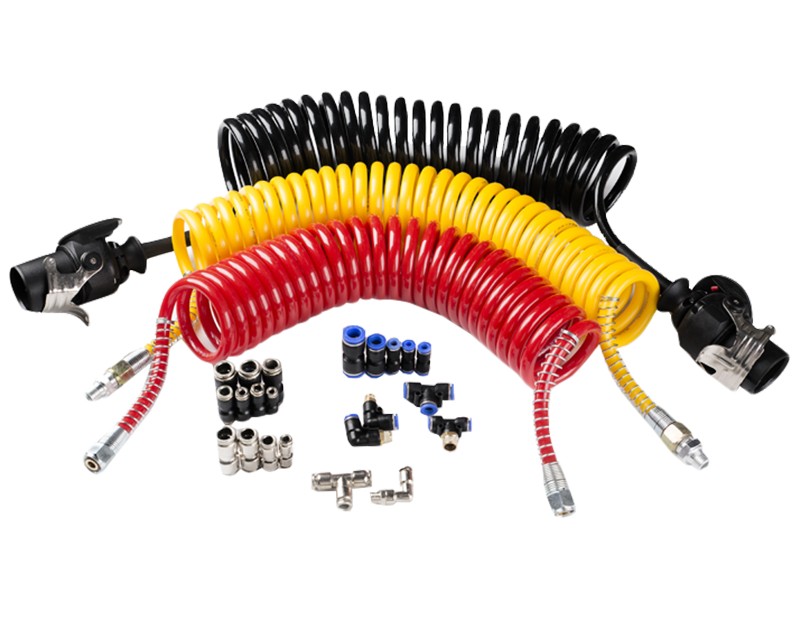

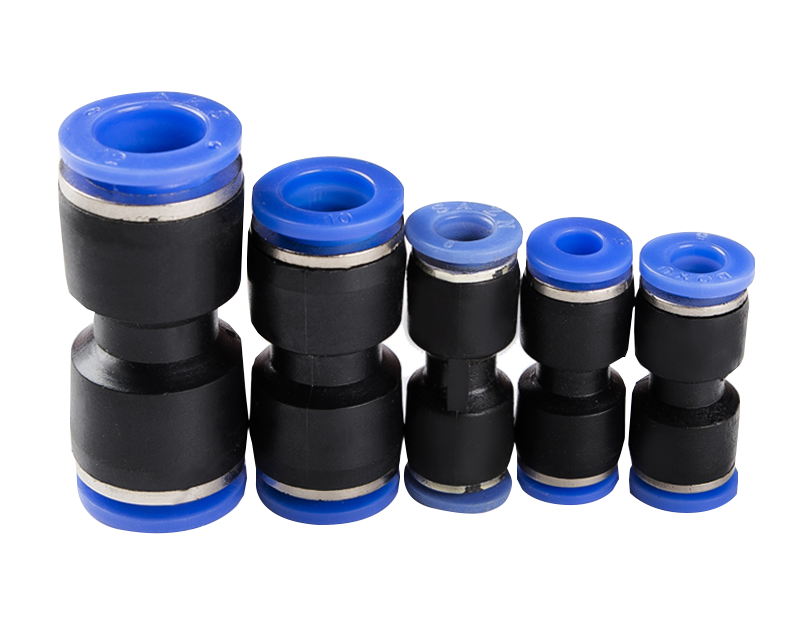

Push-to-Connect Fittings: These user-friendly fittings simplify assembly by allowing users to insert tubing into the fitting, forming a secure connection. Varieties include straight connectors, elbows, tees, and more, catering to diverse configuration needs.

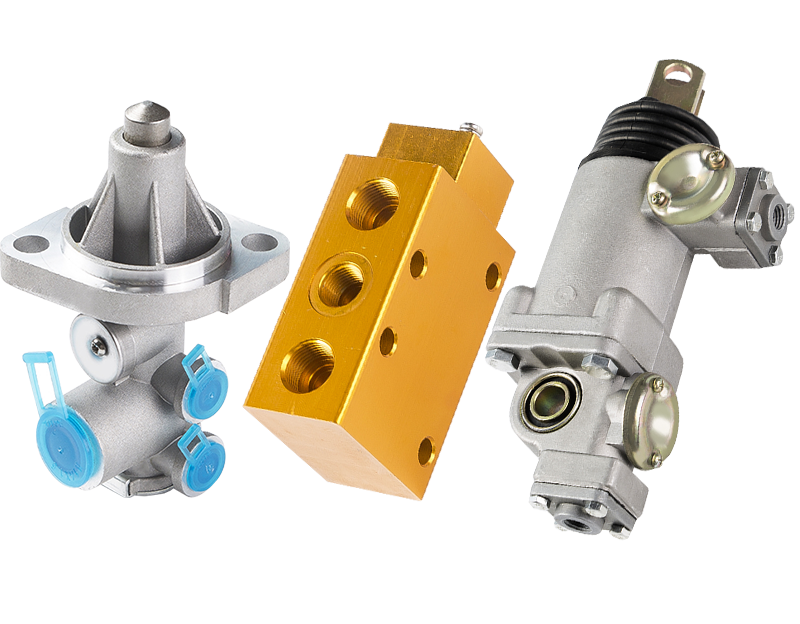

Compression Fittings: Ideal for high-pressure scenarios, compression fittings employ a threaded nut and ferrule to compress tubing against the fitting, creating a secure seal. These fittings are indispensable for critical applications where reliability is paramount.

Barbed Fittings: Featuring ridges or barbs on their surface, barbed fittings grip tubing when inserted and are ideal for low-pressure applications, often used with flexible tubing.

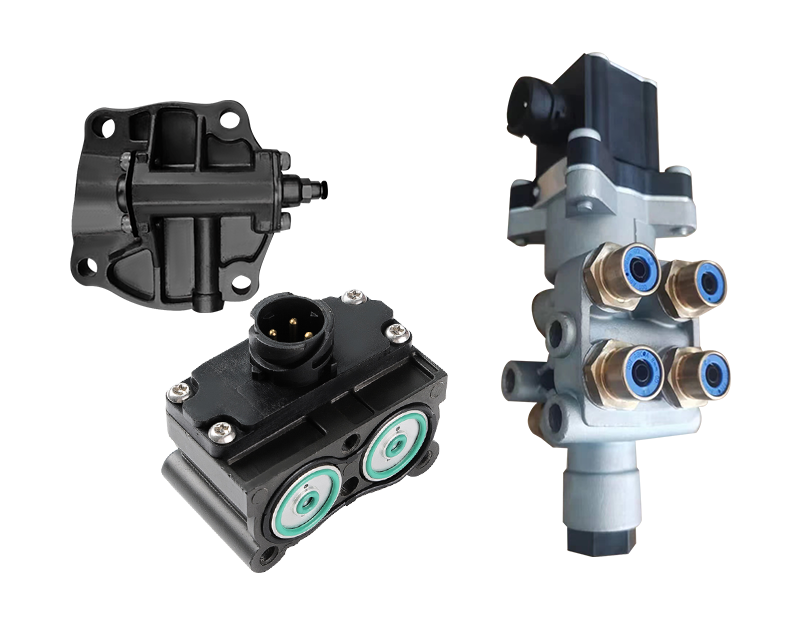

Quick Disconnect Couplings: These fittings enable rapid and effortless connection and disconnection of pneumatic components, making them invaluable in situations requiring frequent adjustments or maintenance.

Swivel Fittings: Swivel fittings include a rotating joint that permits tubing to pivot or rotate while maintaining a sealed connection. They provide flexibility and are essential in scenarios where tubing movement is required.

Applications of Pneumatic Fittings

The versatility of pneumatic fittings extends across various industries and applications:

Manufacturing and Automation: Pneumatic fittings are crucial in automated manufacturing processes such as conveyor systems, pick-and-place robots, and assembly lines. They provide precise control over motion and operate efficiently at high speeds.

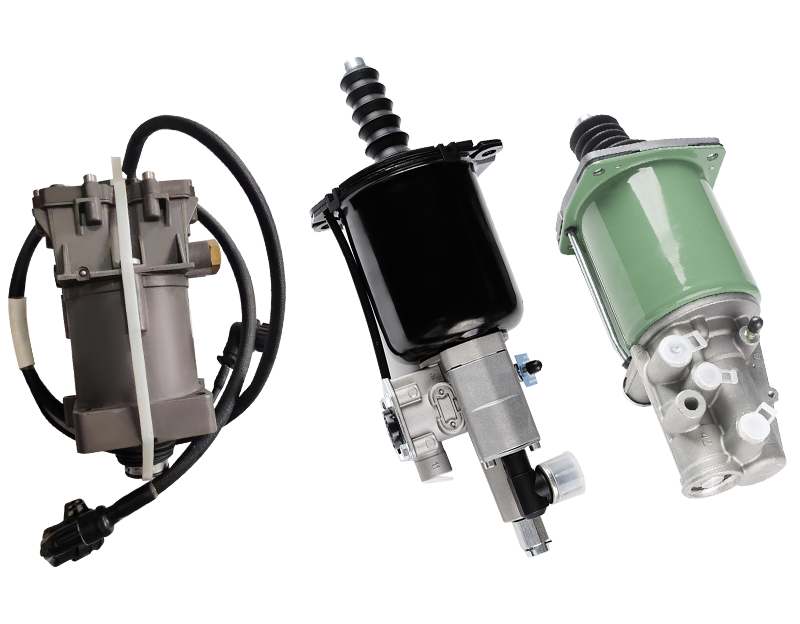

Transportation: The automotive and aerospace sectors heavily rely on pneumatic fittings for applications like braking systems, suspension mechanisms, and pneumatic tools, contributing to safety and performance.

Medical Equipment: Pneumatic fittings are instrumental in medical devices and equipment, including ventilators, dental chairs, and diagnostic instruments, where precision and reliability are non-negotiable.

Food and Beverage Industry: Pneumatic fittings made from FDA-approved materials are staples in food processing and packaging machinery, ensuring compliance with strict hygiene standards.

Mining and Construction: Pneumatic fittings play a vital role in pneumatic tools, drills, and machinery used in demanding mining and construction applications, where durability and reliability are paramount.

Energy and Utilities: Power plants and water treatment facilities leverage pneumatic systems, utilizing pneumatic fittings for valve control, actuation, and other critical operations, ensuring uninterrupted energy supply and clean water distribution.

Laboratory and Research: Laboratories and research facilities utilize pneumatic fittings to control gases, fluids, and vacuum systems, facilitating a wide range of experiments and scientific investigations.

English

English Español

Español