Maintaining proper operation in cold environments is a key challenge for Truck Air Dryers as they need to overcome the impact of low temperatures on equipment performance and operating efficiency. Here’s a detailed description of how Truck Air Dryers keep working in cold environments:

1. Temperature control:

Heating Element: Some premium Truck Air Dryers are equipped with heating elements to increase the temperature inside the unit in cold environments. This prevents the equipment from freezing or condensation due to low temperatures, ensuring that the drying process is not affected.

Insulation materials: The device's casing and key components may be wrapped with insulation materials to reduce heat loss and keep the internal temperature stable.

2. Special treatment of adsorbent materials:

Anti-freeze properties: For dryers using adsorption technology, the adsorbent material may have been specially treated to improve its anti-freeze properties. In this way, even in low-temperature environments, the adsorbent material can maintain its adsorption capacity and is not prone to freezing or failure.

3. Treatment of condensate water:

Anti-icing design: In condensing dryers, a special condensate drainage system may be used to prevent condensate from freezing and clogging in cold environments. This may include heating the exhaust pipe or using antifreeze.

4. Maintenance and maintenance:

Regular inspections: In cold environments, the working status of Truck Air Dryers should be checked more frequently to ensure that all components are functioning properly.

Replace parts: If any parts are found to be damaged or failed due to low temperature, they should be replaced in time to ensure the normal operation of the equipment.

5. Installation location and environment optimization:

Shelter from wind and snow: The installation location should be protected from wind and snow as much as possible to reduce the impact of the external environment on the equipment.

Insulation measures: At the installation site, additional insulation measures can be taken, such as building an insulation shed or covering the equipment with insulation materials, to reduce heat loss.

In general, Truck Air Dryers can maintain normal operation in cold environments through temperature control, special treatment of adsorbent materials, condensation water treatment, intelligent control systems, maintenance and upkeep, and installation location and environment optimization. Together, these measures ensure the dryer's stability and reliability in extreme climate conditions.

CATEGORIES

- Automatic Slack Adjuster

- Manual Slack Adjuster

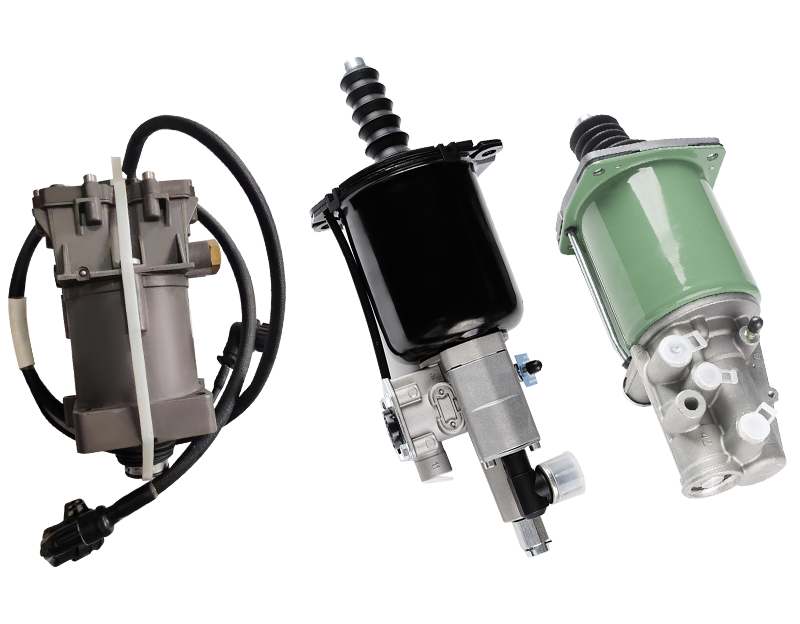

- Air Dryer

- Brake Chamber

- Clutch Servo

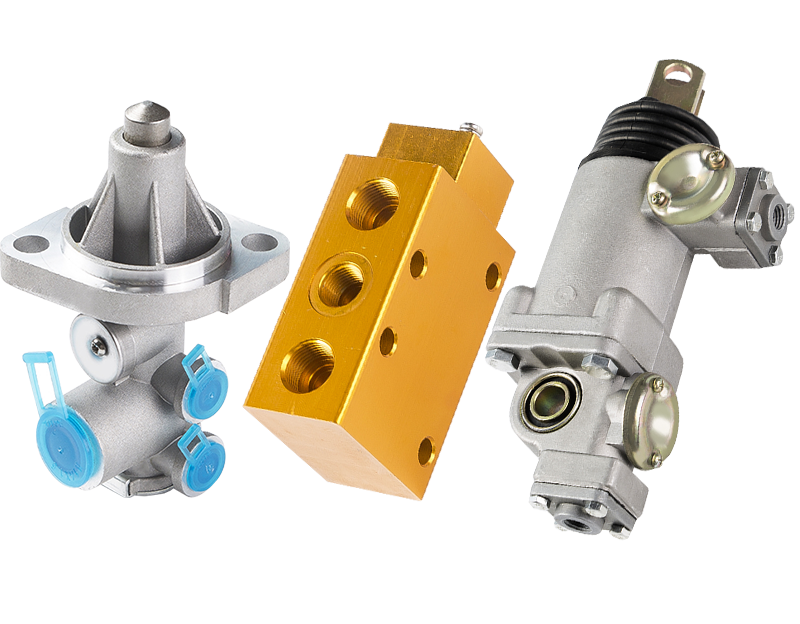

- Leveling Valve

- Gearbox Valve

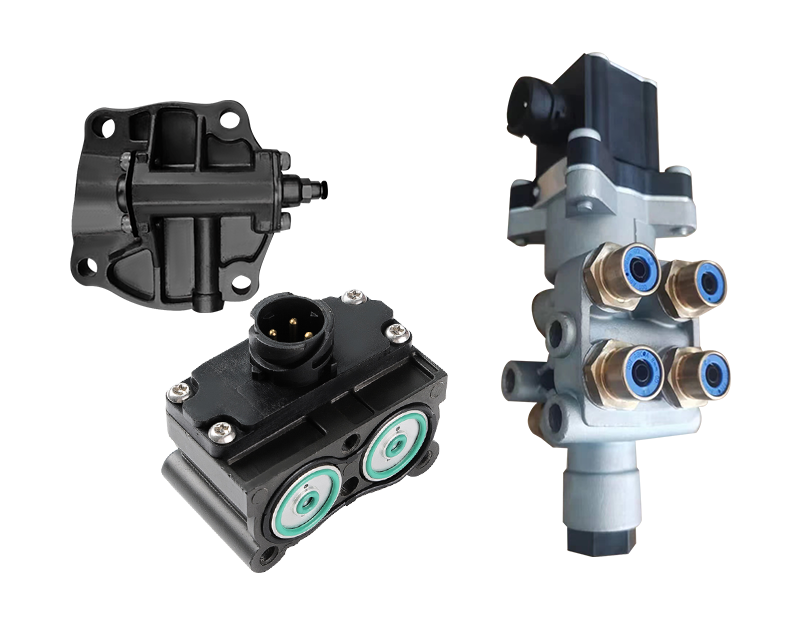

- Solenoid Valve

- Shift Knob

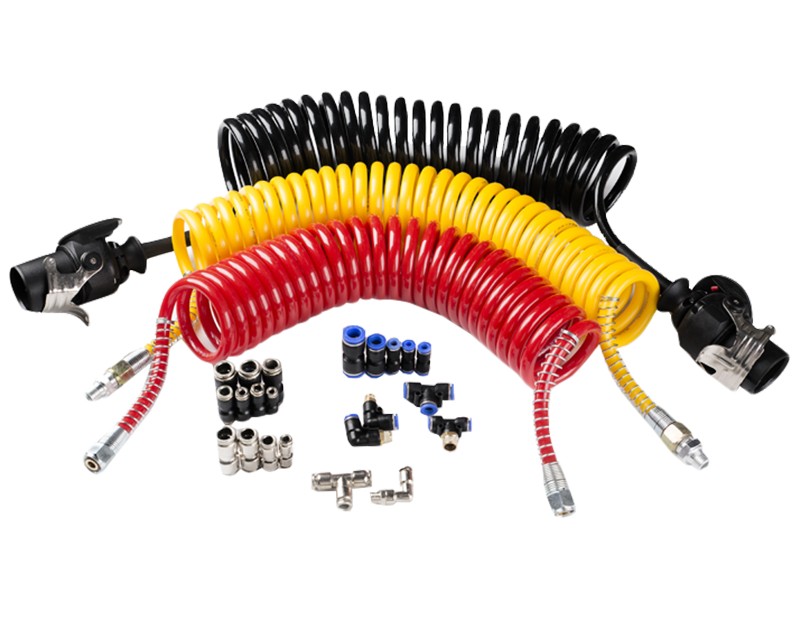

- Air Hose

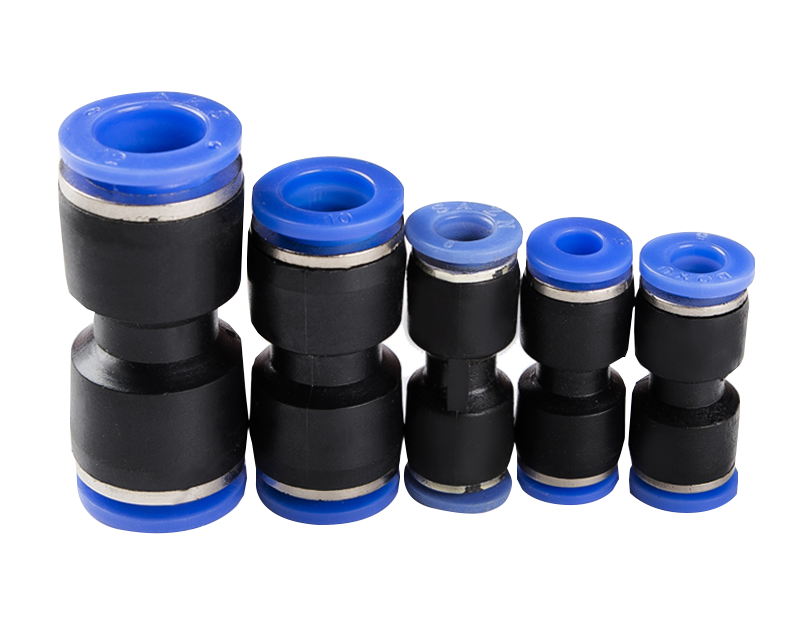

- Quick Coupling

- Pneumatic Fittings

English

English Español

Español