As a vital component in the vehicle system, the air dryer has a complex and efficient process of filtering out water vapor and other pollutants, ensuring the quality of compressed air and the stable operation of the system. The saturated wet air produced by the air compressor is first cooled by the cooling pipe. This step helps to reduce the air temperature, making it easier for water vapor to condense and separate. The cooled air then enters the filter cartridge, which is equipped with a high-efficiency gas-liquid filter. The filter can intercept and capture oil mist, moisture, dust and mechanical impurities in the air, ensuring that the air entering the dryer is relatively pure.

The air after preliminary filtration enters the dryer, which is filled with high-performance adsorbents. The selection of adsorbents is usually based on their adsorption capacity, chemical stability and regeneration performance. The adsorbent has a large number of microporous structures inside, which provide a huge surface area, allowing the adsorbent to efficiently adsorb water vapor molecules in the air. When the wet air comes into contact with the surface of the adsorbent, the water vapor molecules are adsorbed into the micropores, thereby achieving deep drying of the air. The dried air is transported to the locomotive main air cylinder through the dry check valve at the bottom of the dryer. At the same time, part of the dry air also enters the regeneration air cylinder through the throttle hole to prepare for the subsequent regeneration process.

When the air compressor stops working, the control circuit will activate the discharge electric air valve to energize it. The opening of the discharge electric air valve allows the pressurized air in the regeneration air cylinder to enter the upper part of the bellows of the discharge valve, pushing the bellows and the bellows rod downward, thereby opening the discharge valve port.

The pressurized air, oil, moisture, dust and mechanical impurities in the filter cylinder, dryer cylinder and the pipeline from the air outlet of the air compressor to the dryer cylinder are discharged from the system through the open discharge valve port. At the same time, the dry pressurized air in the regeneration air cylinder enters the dryer cylinder through the throttle hole and expands into ultra-dry air close to atmospheric pressure. The ultra-dry air passes through the adsorbent in the opposite direction to the adsorption drying process, and uses the characteristics of increased air volume and reduced pressure during expansion, as well as the low relative humidity of the ultra-dry air, to effectively "take away" the water vapor molecules adsorbed on the adsorbent. The purged adsorbent gradually restores its dry state and is ready for the next round of adsorption drying process. The completion of the regeneration process marks the end of a complete working cycle of the air dryer and is also ready for the start of the next cycle.

In order to ensure the continued efficient operation of the air dryer, it needs to be maintained regularly. This includes checking the saturation of the adsorbent, replacing aging filters and adsorbents, cleaning the dryer cylinder and drain valve, etc. By monitoring parameters such as the quality, pressure and temperature of the output air, potential problems can be discovered and solved in a timely manner. According to the specific needs of the vehicle system and changes in the operating environment, the parameters of the air dryer can be adaptively adjusted to optimize its performance.

The air dryer ensures the dryness and cleanliness of the air in the vehicle system through its sophisticated adsorption drying and regeneration process. The stability and efficiency of this process are important for preventing winter icing, extending the service life of the air valve, and improving the overall performance of the vehicle system.

How does the air dryer filter out water vapor and other pollutants?

CATEGORIES

- Automatic Slack Adjuster

- Manual Slack Adjuster

- Air Dryer

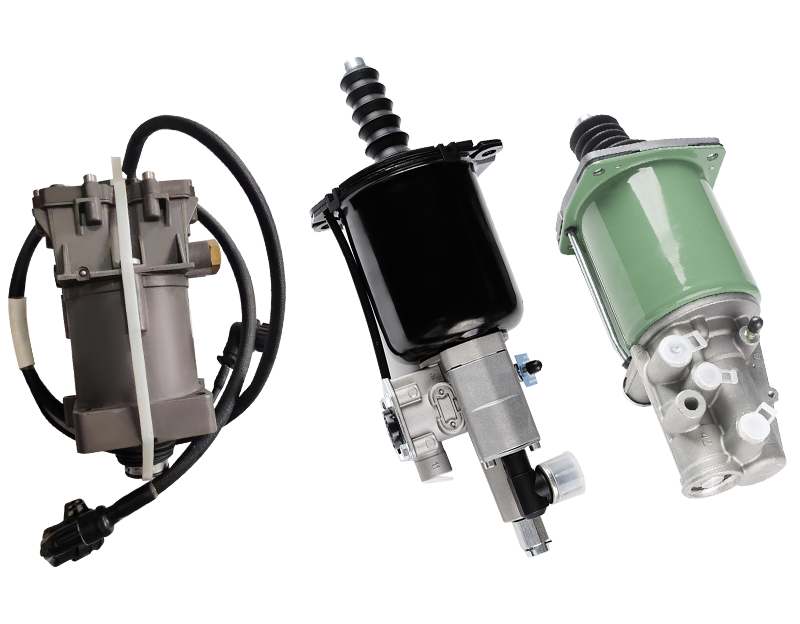

- Brake Chamber

- Clutch Servo

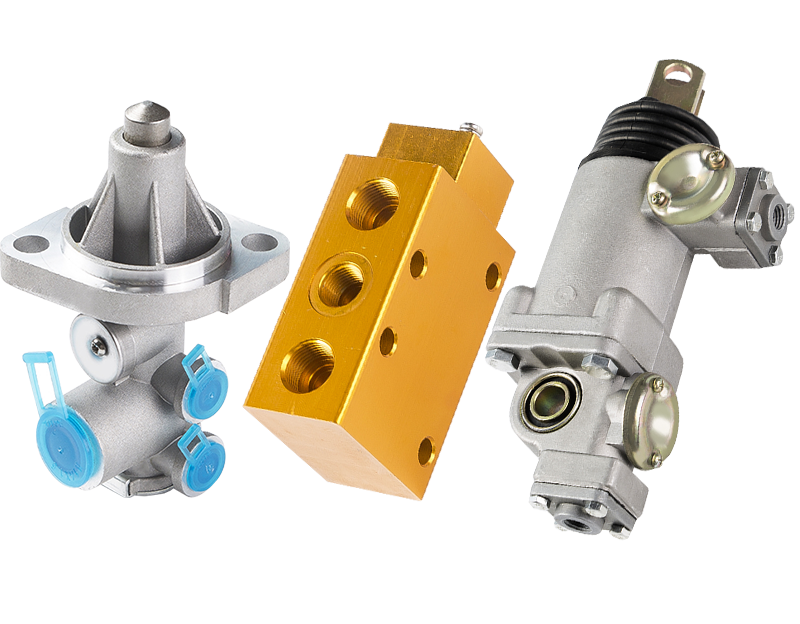

- Leveling Valve

- Gearbox Valve

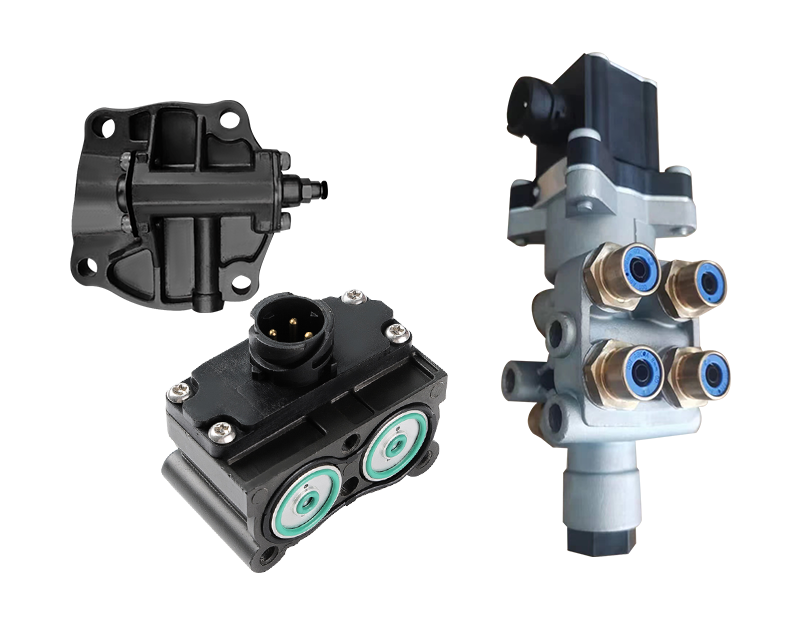

- Solenoid Valve

- Shift Knob

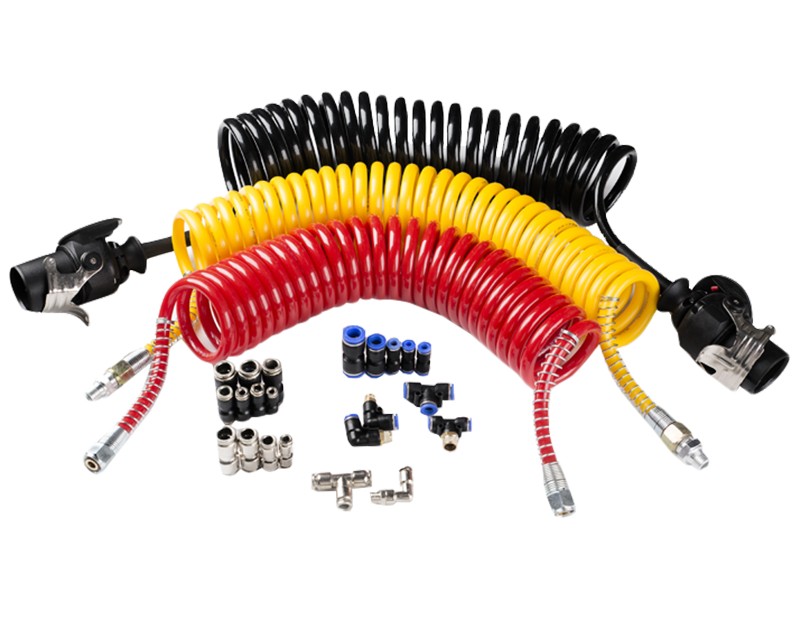

- Air Hose

- Quick Coupling

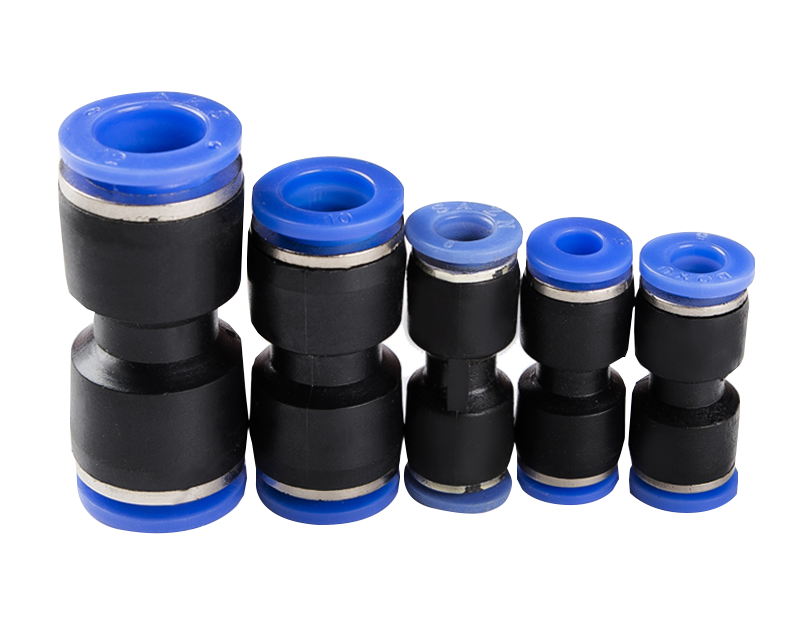

- Pneumatic Fittings

English

English Español

Español