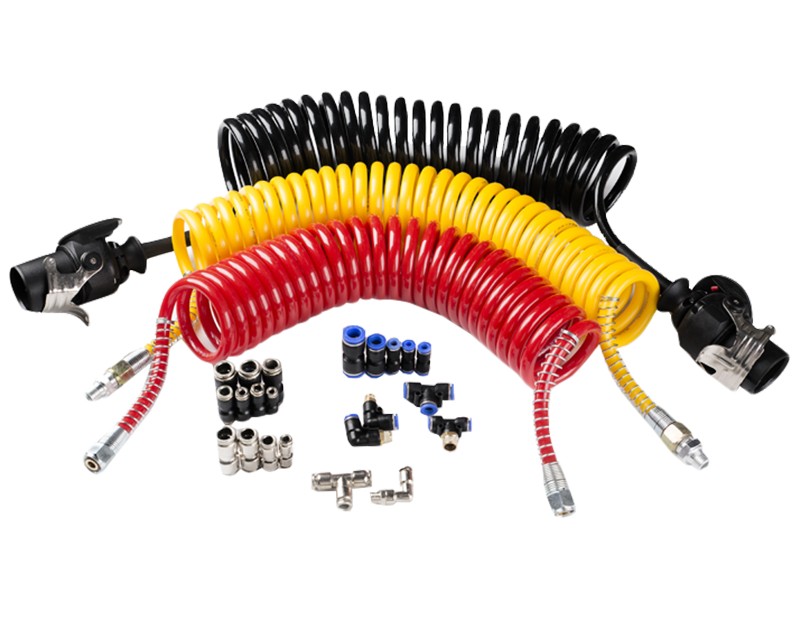

Quick couplings, also known as quick disconnects or quick release couplings, play a vital role in a wide range of industries, including manufacturing, automotive, aerospace, and hydraulic systems. These couplings enable fast and reliable connections and disconnections of fluid and gas lines, electrical connections, and other mechanical systems. As we look into the future, several innovations and trends are shaping the quick coupling industry. Here are some key developments to consider:

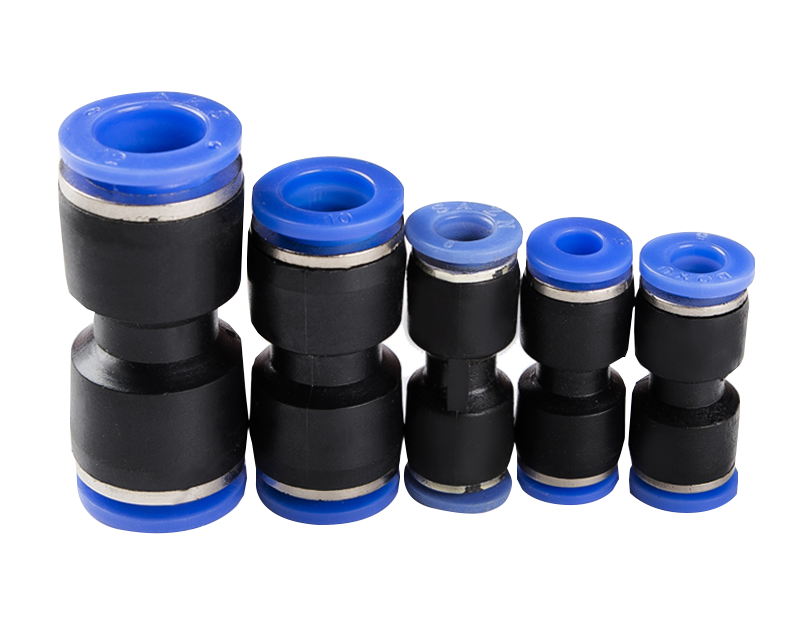

Advanced Materials: The future of quick couplings lies in the development and implementation of advanced materials. Traditional couplings are often made from metals like stainless steel or brass. However, there is an increasing demand for lightweight and corrosion-resistant materials, such as composite materials or high-performance plastics. These materials offer improved durability, chemical resistance, and reduced weight, making them suitable for a broader range of applications.

Smart and Connected Couplings: With the rise of the Internet of Things (IoT) and Industry 4.0, quick couplings are becoming smarter and more connected. Integrated sensors and communication technologies allow real-time monitoring of coupling performance, leak detection, temperature, pressure, and other parameters. This data can be utilized for predictive maintenance, optimizing system performance, and ensuring operational safety.

Quick Couplings for High-Pressure Applications: Many industries, such as oil and gas, aerospace, and automotive, require quick couplings that can withstand high-pressure conditions. In response to this demand, manufacturers are developing couplings capable of handling higher pressure ratings while maintaining quick and easy connection features. These advancements ensure the safe and efficient operation of systems under extreme conditions.

Improved Safety Features: Safety is a critical aspect of quick couplings, especially when dealing with hazardous fluids or high-pressure systems. Future couplings will feature enhanced safety mechanisms, such as automatic locking systems, pressure relief valves, and color-coded indicators to prevent accidental disconnections and ensure proper alignment during connection.

Miniaturization and Compact Designs: As technology continues to advance, devices and systems are becoming smaller and more compact. Quick couplings must adapt to these miniaturization trends, offering reduced size and weight while maintaining their performance capabilities. Miniature quick couplings enable connections in confined spaces, enhancing flexibility in various applications, including medical devices, electronics, and robotics.

Eco-Friendly Coupling Solutions: Sustainability is an increasingly important factor in industrial operations. Quick coupling manufacturers are focusing on developing environmentally friendly solutions, including couplings with minimal fluid leakage, low energy consumption during connection, and recyclable or biodegradable materials. These innovations contribute to reducing environmental impact and improving overall system efficiency.

Customization and Modular Systems: Quick coupling manufacturers are embracing the demand for customization and modular systems. Customers are seeking couplings that can be tailored to their specific needs and easily integrated into existing setups. Modular designs enable quick and flexible assembly, disassembly, and reconfiguration of fluid or gas lines, promoting efficiency and adaptability.

3D Printing and Additive Manufacturing: Additive manufacturing, such as 3D printing, is revolutionizing various industries. In the quick coupling sector, it allows for complex and customized designs, rapid prototyping, and cost-effective production. 3D printing enables manufacturers to create intricate internal geometries, optimize flow characteristics, and reduce weight while maintaining structural integrity.

These innovations and trends demonstrate that the future of quick couplings is dynamic and evolving. The industry is driven by the need for improved performance, safety, sustainability, and adaptability to meet the ever-changing demands of modern applications and industries.

English

English Español

Español