Truck slack adjusters are critical components in maintaining proper brake tension and ensuring the effective operation of the braking system in trucks. These devices play a vital role in controlling the distance between the brake shoes and the brake drum, which directly impacts the truck's ability to stop safely and efficiently.

The primary function of truck slack adjusters is to compensate for brake shoe wear. As the brake lining wears down over time, the gap between the brake shoe and the brake drum increases, resulting in reduced braking performance. Slack adjusters automatically adjust this gap, ensuring that the brake shoes are in constant contact with the brake drum, regardless of wear.

Proper brake tension is crucial as it enables the brake shoes to generate sufficient friction against the brake drum, effectively slowing down or stopping the truck when the brakes are applied. If the brake tension is too loose, the brakes may have a delayed response or fail to engage properly, compromising the safety of the vehicle and its occupants. On the other hand, excessive brake tension can cause unnecessary friction, resulting in accelerated wear of brake components and reduced braking efficiency.

Maintaining the correct brake tension is not only essential for safety but also for maximizing the lifespan of the braking system. By ensuring consistent contact between the brake shoes and the brake drum, the slack adjusters help distribute braking forces evenly, reducing the chances of uneven wear and premature brake component failure.

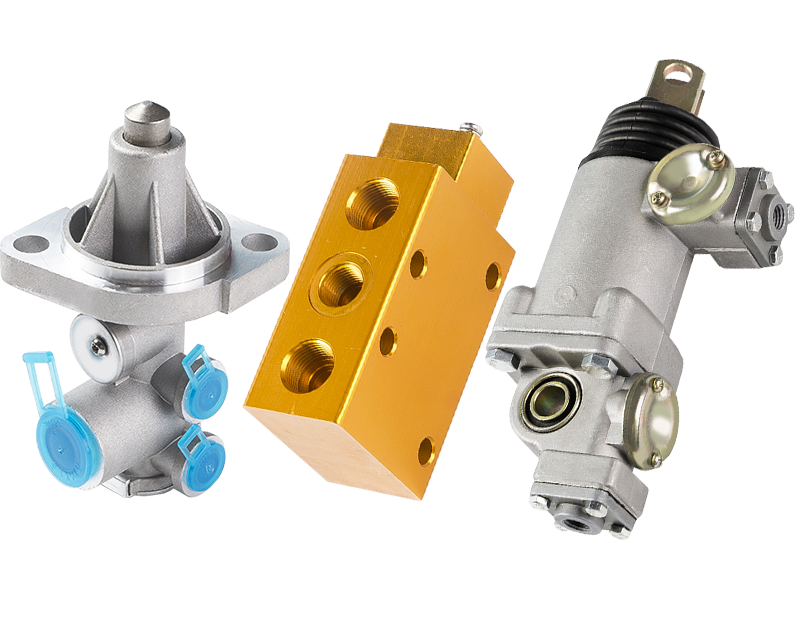

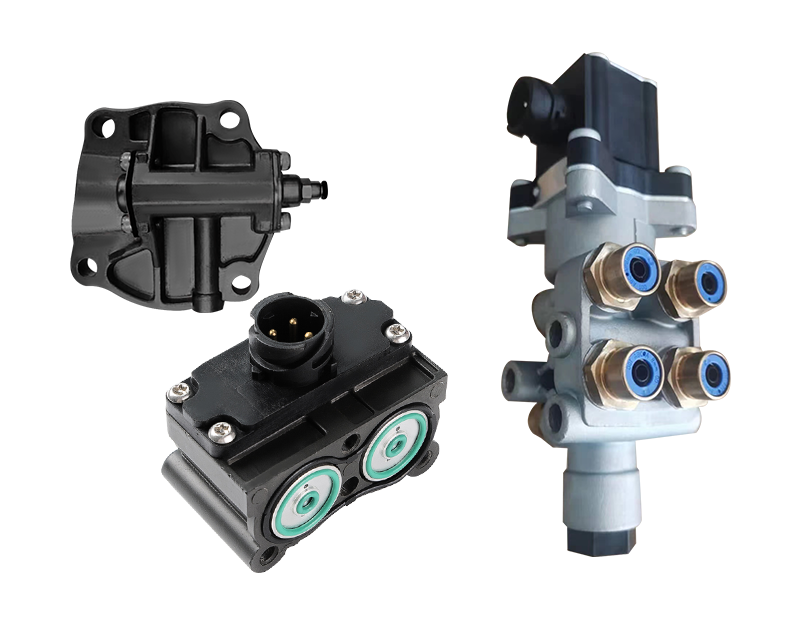

There are different types of slack adjusters available, including manual and automatic variants. Manual slack adjusters require regular manual adjustments to compensate for brake shoe wear, whereas automatic slack adjusters self-adjust as the brake lining wears, maintaining proper tension without the need for manual intervention.

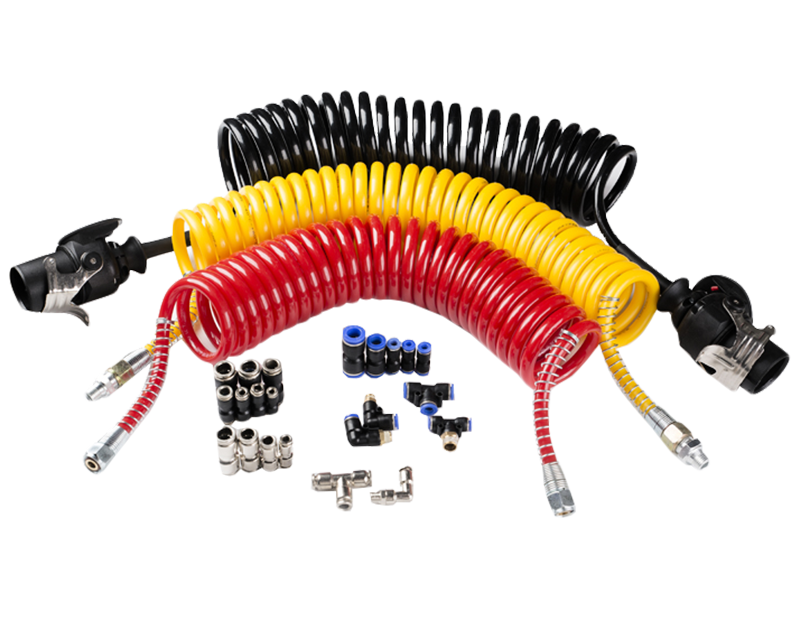

To ensure the optimal performance of truck slack adjusters, regular inspection and maintenance are necessary. The slack adjusters should be checked for signs of wear, damage, or excessive corrosion. Any issues should be addressed promptly to prevent brake system malfunctions. Additionally, proper lubrication of the slack adjusters is crucial to ensure smooth operation and minimize wear.

In conclusion, truck slack adjusters play a crucial role in maintaining proper brake tension and ensuring the efficient and safe operation of the truck's braking system. These devices compensate for brake shoe wear, allowing consistent contact between the brake shoes and the brake drum. By doing so, slack adjusters enhance braking performance, maximize the lifespan of brake components, and contribute to overall road safety.

English

English Español

Español