Height control leveling valves are a crucial component of a vehicle's suspension system. They help maintain a constant ride height regardless of the load carried by the vehicle, ensuring optimal performance and safety.

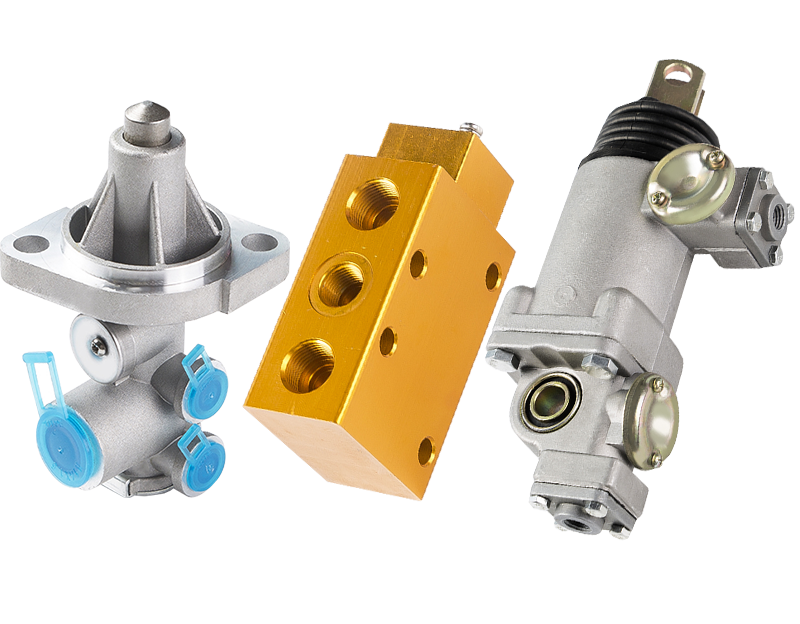

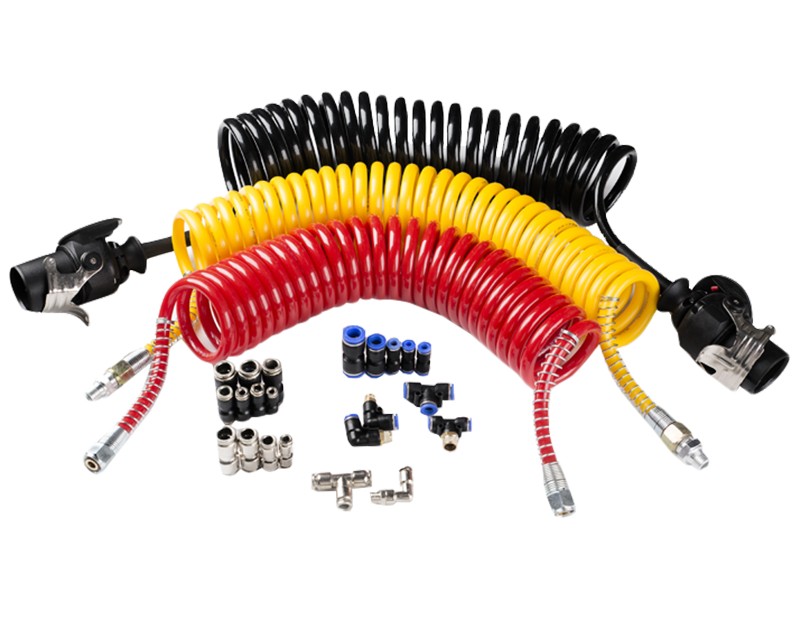

The basic function of a height control leveling valve is to control the flow of air between the air suspension bags or springs and the compressor. When the vehicle is loaded, the valve senses the change in height and adjusts the flow of air to the suspension bags or springs to compensate for the added weight. This results in a level ride height and improved stability, handling, and braking performance.

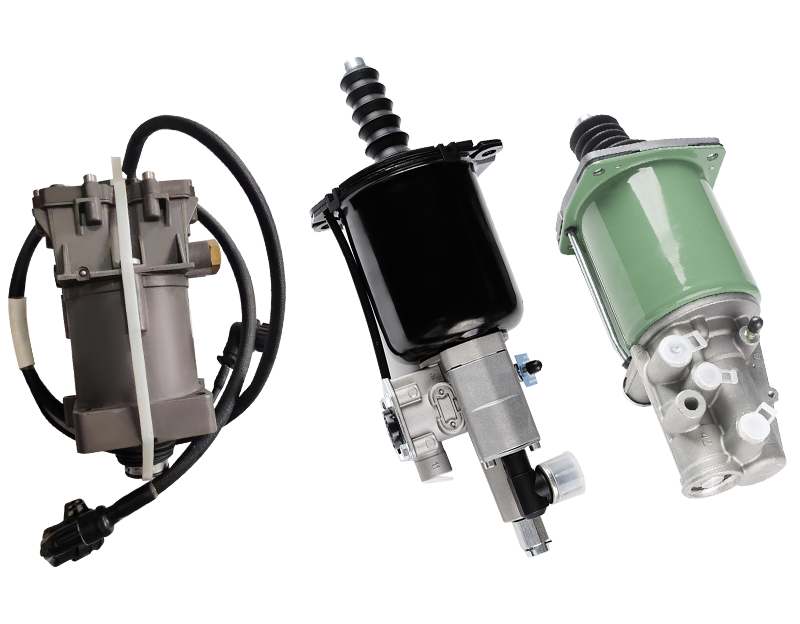

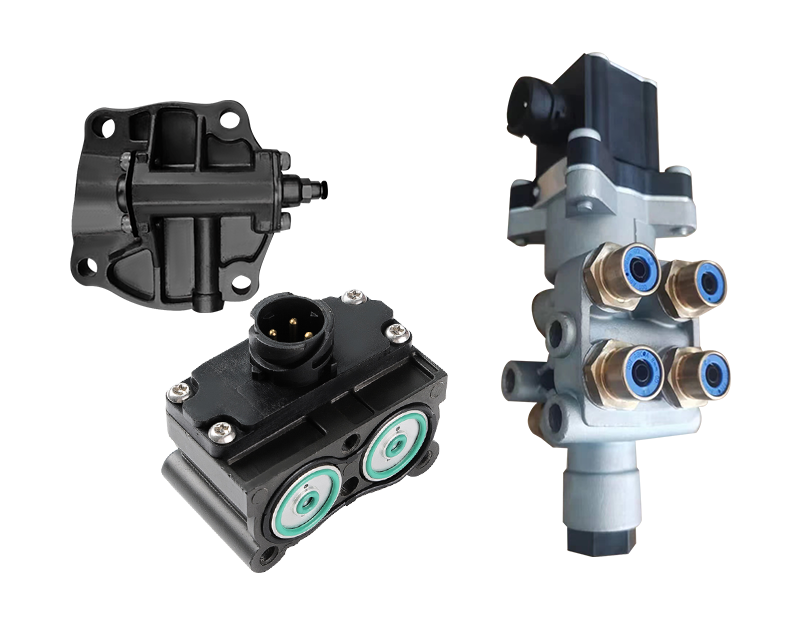

There are two types of height control leveling valves: mechanical and electronic. Mechanical valves use a combination of springs and air pressure to adjust the flow of air, while electronic valves use sensors and a control module to make precise adjustments. Electronic valves are more sophisticated and provide better accuracy and control, but they are also more expensive.

Height control leveling valves are essential for maintaining the proper balance and stability of a vehicle, especially when carrying heavy loads. They help prevent the suspension from bottoming out, which can cause damage to the suspension components and reduce the vehicle's handling and stability. They also help prevent the suspension from becoming too stiff, which can cause a harsh ride and reduce comfort.

In conclusion, height control leveling valves are an essential component of a vehicle's suspension system. They help ensure a safe, comfortable, and stable ride, regardless of the load carried by the vehicle. Understanding how they work and why they matter is important for anyone involved in the maintenance or operation of vehicles with air suspension systems.

English

English Español

Español