The worm is the core transmission component in the Manual Slack Adjusters. It is usually a long spiral structure with precise spiral teeth on its surface. These spiral teeth mesh with the tooth grooves on the worm wheel to achieve the transmission of rotational force. The material of the worm is usually high-strength, wear-resistant alloy steel to ensure that it can maintain sufficient strength and durability during use.

The worm is tightly meshed with the worm wheel through the spiral teeth on its surface, and can accurately and stably transmit the externally applied rotational force to the worm wheel. This transmission method ensures that the adjustment arm has sufficient accuracy and stability when adjusting the brake clearance.

When the brake clearance needs to be adjusted, the rotation of the worm will drive the worm wheel to rotate together. The rotation of the worm wheel further converts the rotational motion into linear motion through mechanisms such as camshafts, thereby adjusting the gap between the brake pad and the brake hub. This adjustment method is not only efficient, but also ensures the accuracy and consistency of the gap adjustment.

After the adjustment is completed, the position of the worm will be locked to prevent the adjustment arm from retreating due to vibration or impact during the braking process. This limiting and fixing action ensures the constant braking clearance and the stability of the braking system, thereby improving the braking performance and safety of the vehicle.

The meshing relationship between the worm and the worm wheel is the key to achieving clearance adjustment. The helical teeth of the worm and the tooth grooves of the worm wheel are closely matched to ensure the smooth transmission of the rotational force and the accuracy of the clearance adjustment. The worm is usually installed in the housing of the adjustment arm, and the housing provides the necessary support and protection for the worm. At the same time, the limiting device on the housing also ensures the stability and reliability of the worm during the adjustment process. During the adjustment process, the rotation of the worm will drive the adjusting screw and other components to move together, thereby achieving the adjustment of the clearance. The synergy between these components ensures the smooth progress of the adjustment process and the accuracy of the clearance adjustment.

In order to ensure the normal operation of the worm and extend its service life, it needs to be regularly maintained and maintained. Lubricants such as butter need to be injected from the oil nozzle regularly to reduce the wear and friction between the worm and the worm wheel. The choice of lubricant should be appropriately adjusted according to the use environment and temperature. During the adjustment process, metal tools should be avoided from hitting the worm shaft and other parts to prevent damage to the tooth surface of the worm and worm wheel. The wear of the worm and worm wheel, as well as the integrity of the limit device on the housing should be checked regularly. If any abnormality is found, it should be repaired or replaced in time.

The worm in the Manual Slack Adjusters plays an important role in the adjustment process, such as accurately transmitting torque, achieving efficient clearance adjustment, and providing reliable limit and fixation. It is one of the key components to ensure the normal operation and stable performance of the brake system. Therefore, it should be given enough attention and care during use and maintenance.

What role does the worm of the Manual Slack Adjusters play in the adjustment process?

CATEGORIES

- Automatic Slack Adjuster

- Manual Slack Adjuster

- Air Dryer

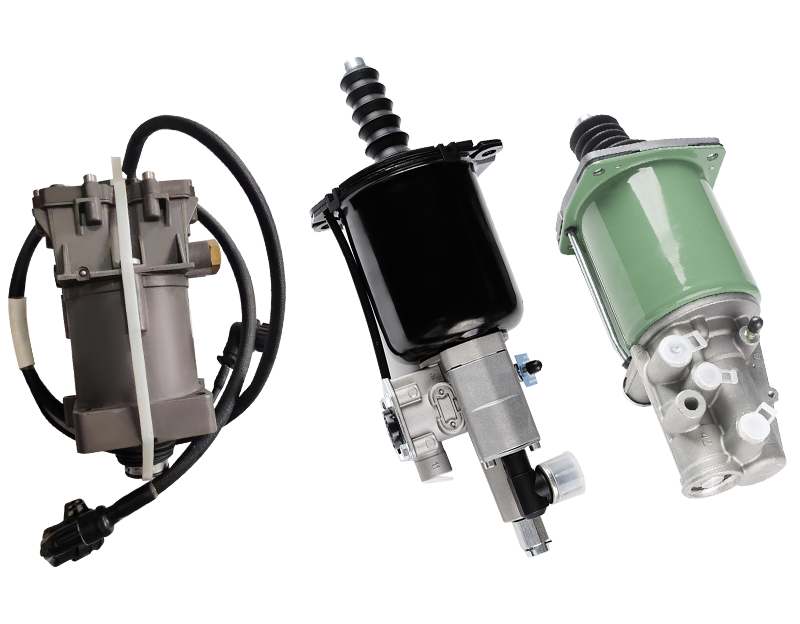

- Brake Chamber

- Clutch Servo

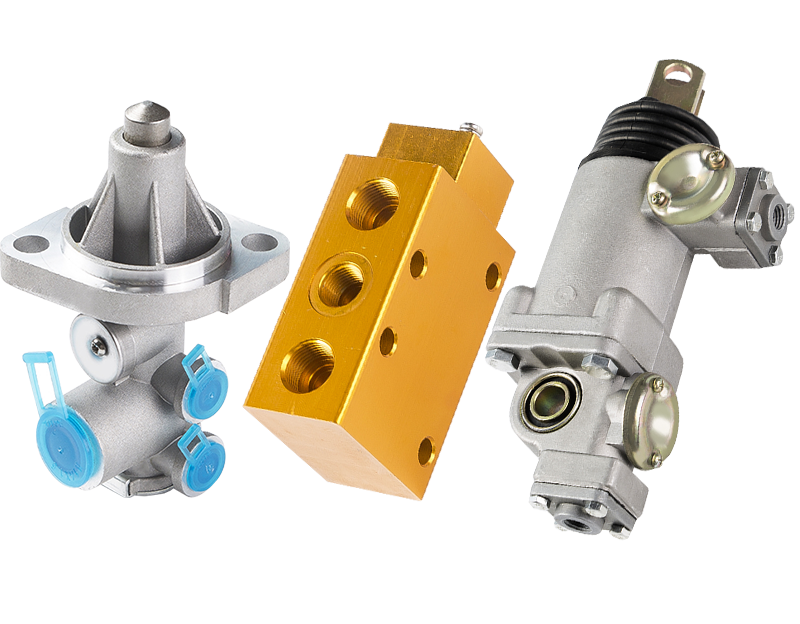

- Leveling Valve

- Gearbox Valve

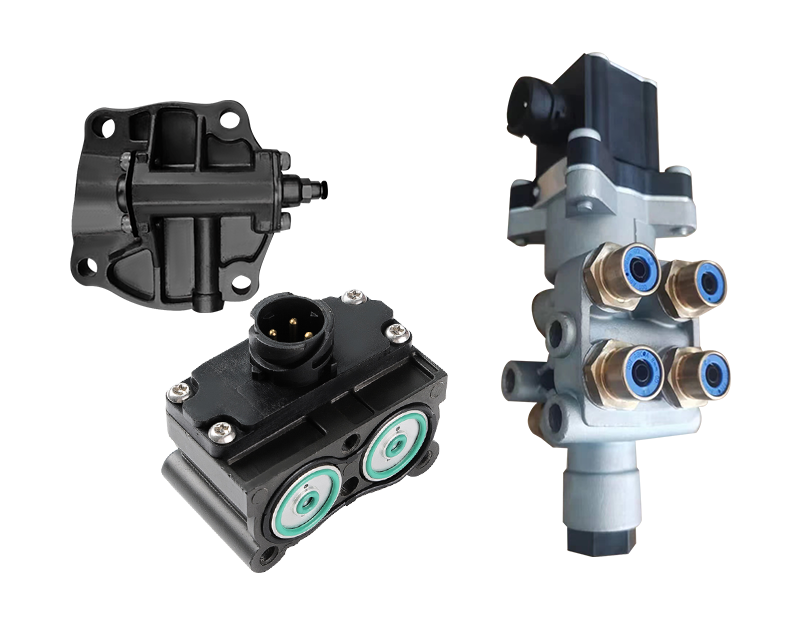

- Solenoid Valve

- Shift Knob

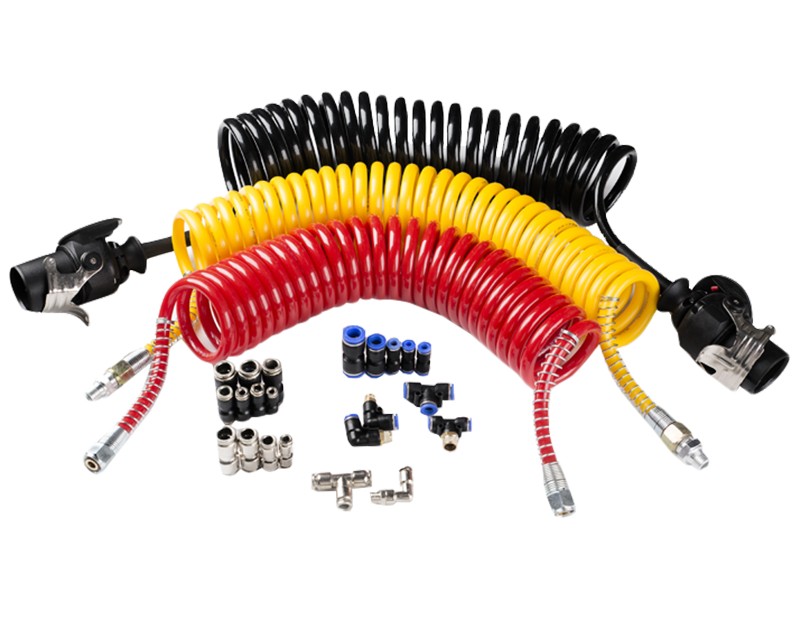

- Air Hose

- Quick Coupling

- Pneumatic Fittings

English

English Español

Español