Brake chambers are integral components within air brake systems, responsible for converting air pressure into mechanical force to engage the brakes. The type of brake chamber required depends on the specific configuration of the brake system and the intended application.

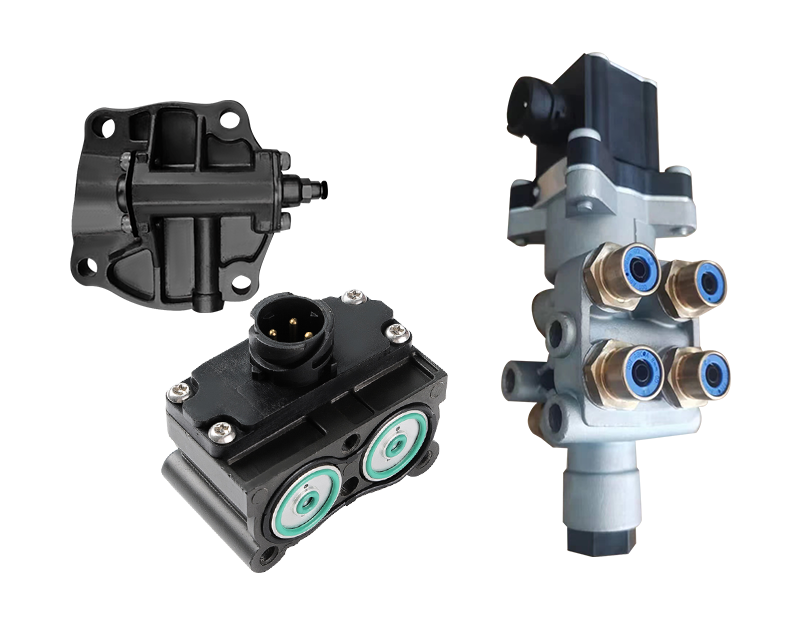

In heavy-duty truck and trailer air brake systems, single diaphragm spring brake chambers are commonly used. These chambers feature a single diaphragm that compresses a spring when air pressure is applied, releasing the spring's energy to engage the brake when the air pressure is released.

For larger brake applications, double diaphragm spring brake chambers are essential. The dual-diaphragm design provides additional force, enhancing braking power. These chambers are suitable for heavy-duty vehicles.

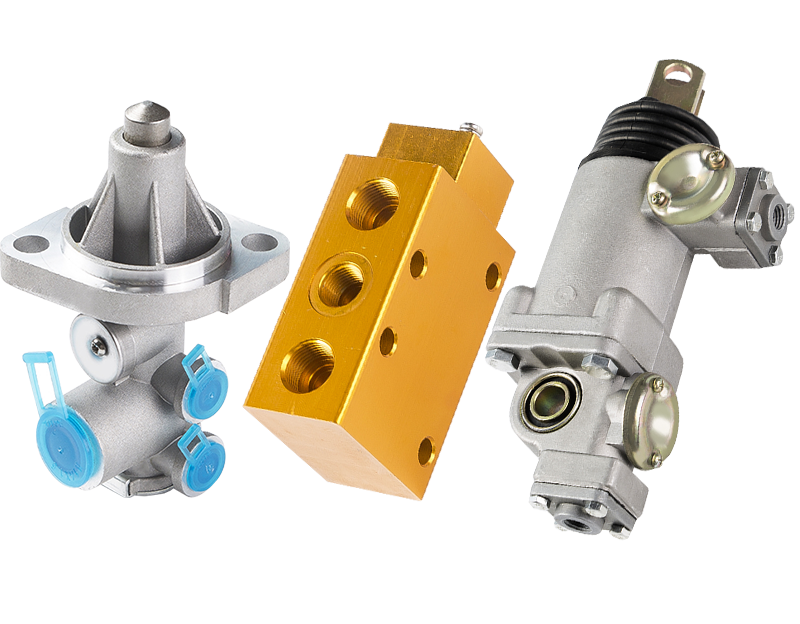

Service brake chambers play a crucial role in the primary braking system of heavy-duty vehicles such as trucks and buses. They are responsible for operating the service brakes during normal vehicle operation. Service brake chambers come in various sizes and configurations to accommodate different vehicle types and weight capacities.

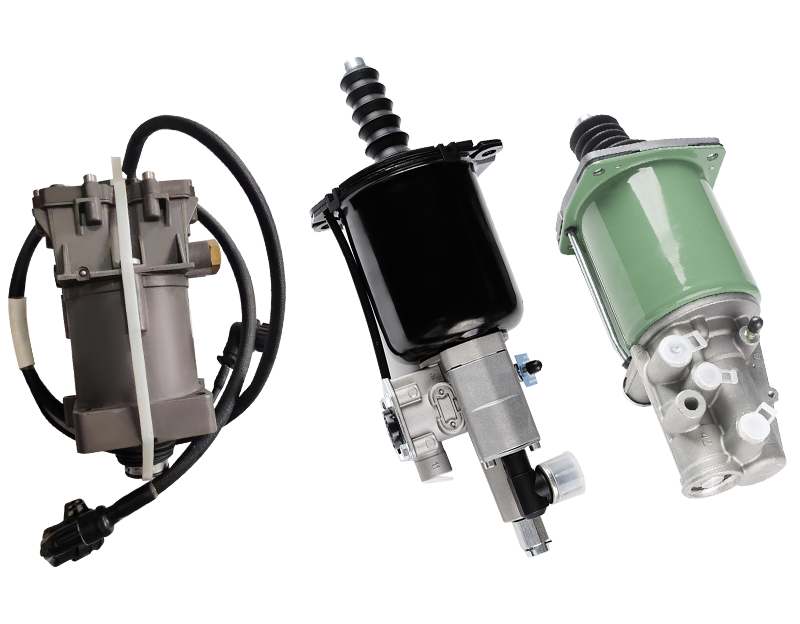

Spring brake chambers, designed for emergency and parking brakes, automatically engage the brakes when air pressure is lost. They are commonly used in combination with service brake chambers and provide an essential safety feature.

Piggyback spring brake chambers integrate both service and spring brake functions into a compact design. This type of chamber is suitable for applications where space is limited, streamlining the installation process.

Compressor-integrated spring brake chambers combine the air compressor with the spring brake system, offering a more compact and space-efficient solution. They are found in certain types of air brake configurations.

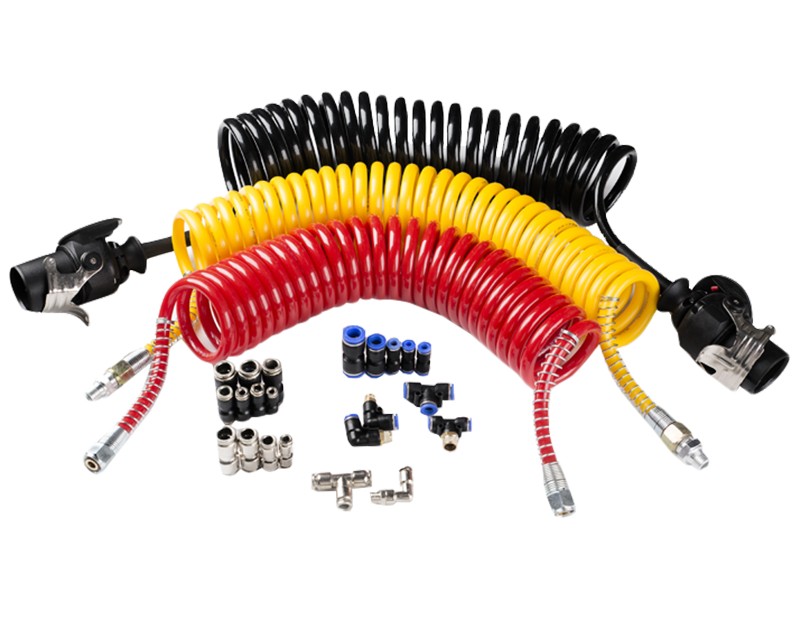

Remote-mounted brake chambers are utilized in specialized applications where space constraints or specific configurations necessitate remote mounting. These chambers are connected to the brake assembly via air hoses, allowing for flexibility in design and installation.

Short-stroke brake chambers are designed for applications where a shorter stroke is desired for quicker brake response. These chambers feature a design that reduces the diaphragm travel distance, enabling faster application and release of the brakes.

Ultimately, the selection of brake chambers is based on factors such as the type of vehicle, weight considerations, brake system configuration, and regulatory requirements. Proper sizing and compatibility with the overall brake system are critical to ensuring safe and effective braking performance. Manufacturers and vehicle specifications provide guidance on the appropriate brake chambers for specific applications, contributing to the overall reliability and safety of the braking system.

English

English Español

Español