Selecting the appropriate pneumatic fittings for high-pressure applications is critical for ensuring the reliability, safety, and efficiency of pneumatic systems. In industries such as aerospace, automotive manufacturing, hydraulic systems, and heavy machinery, where high pressures are common, choosing the right fittings is paramount to prevent leaks, maintain system integrity, and optimize performance.

Compression fittings are widely regarded as suitable options for high-pressure pneumatic applications. These fittings employ a compression mechanism, typically consisting of a ferrule and compression nut, to create a secure seal around the tubing. The compression action ensures a tight and leak-free connection, making compression fittings ideal for systems operating under high pressures. They are commonly used in hydraulic systems, instrumentation, and fluid transfer applications.

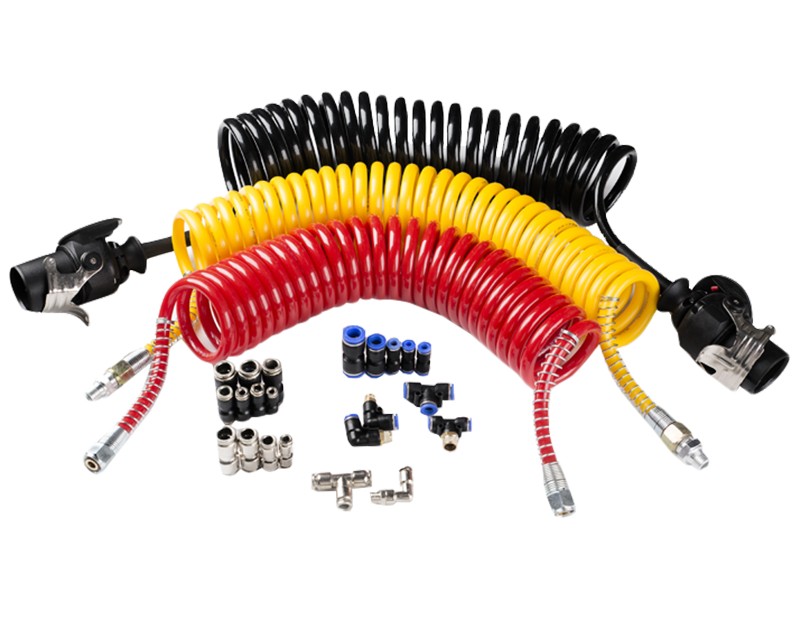

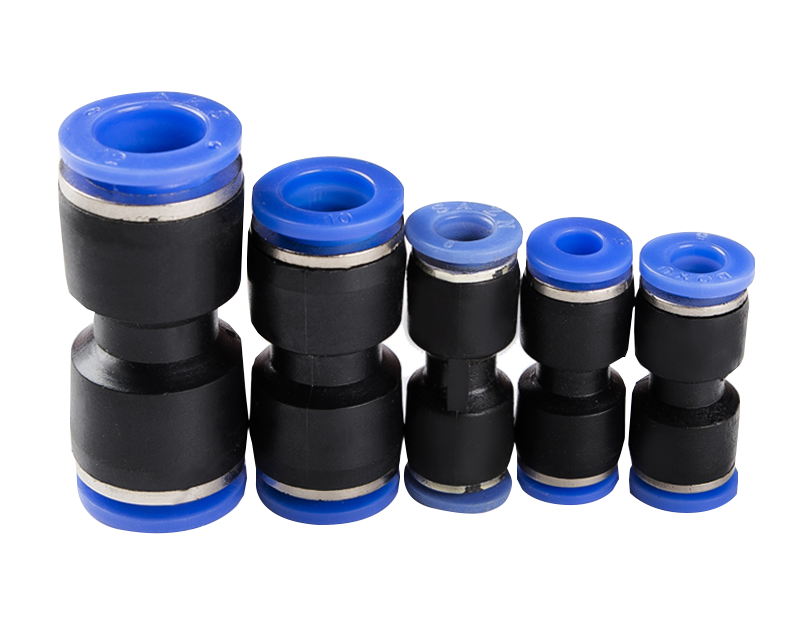

Another popular choice for high-pressure pneumatic systems is push-to-connect fittings, also known as quick-connect fittings. These fittings offer the advantage of rapid assembly without the need for tools or additional components. The push-in design allows tubing to be quickly inserted into the fitting and secured, providing a reliable seal that can withstand elevated pressures. Push-to-connect fittings are widely used in pneumatic tools, air compressors, and industrial automation systems.

Threaded fittings are also commonly employed in high-pressure pneumatic applications. These fittings utilize threaded connections to secure tubing or components in place, offering a robust and reliable solution for systems operating under high pressures. Threaded fittings come in various thread sizes and configurations to accommodate different system requirements, making them versatile options for a wide range of applications.

In industries such as hydraulic systems, construction, and mining, high-pressure hose fittings are indispensable components. These fittings are specifically designed for use with flexible hoses rated for high-pressure applications. They feature a robust construction and specialized sealing mechanisms to ensure leak-free connections even under extreme pressure conditions. High-pressure hose fittings play a crucial role in ensuring the safety and reliability of hydraulic systems and pneumatic equipment.

Hydraulic fittings are another category of fittings well-suited for high-pressure pneumatic applications. Designed to withstand extreme pressures and harsh operating conditions, hydraulic fittings are constructed to provide reliable performance in demanding environments. They come in various configurations and standards, including JIC, SAE, and DIN, to meet the diverse needs of hydraulic and pneumatic systems across different industries.

Double ferrule fittings offer enhanced sealing and gripping action, making them suitable for high-pressure pneumatic applications. These fittings feature a two-piece design with inner and outer ferrules that provide superior sealing performance and resistance to vibration and thermal cycling. Double ferrule fittings are commonly used in instrumentation, process control, and laboratory equipment, where precision and reliability are paramount.

Crimp fittings are designed to provide a permanent attachment to hoses using a crimping tool or machine. These fittings create a secure and leak-free connection by crimping the fitting onto the hose, ensuring a tight seal that can withstand high pressures. Crimp fittings are widely used in hydraulic systems, air brake systems, and refrigeration applications, where reliable connections are essential for safe and efficient operation.

English

English Español

Español