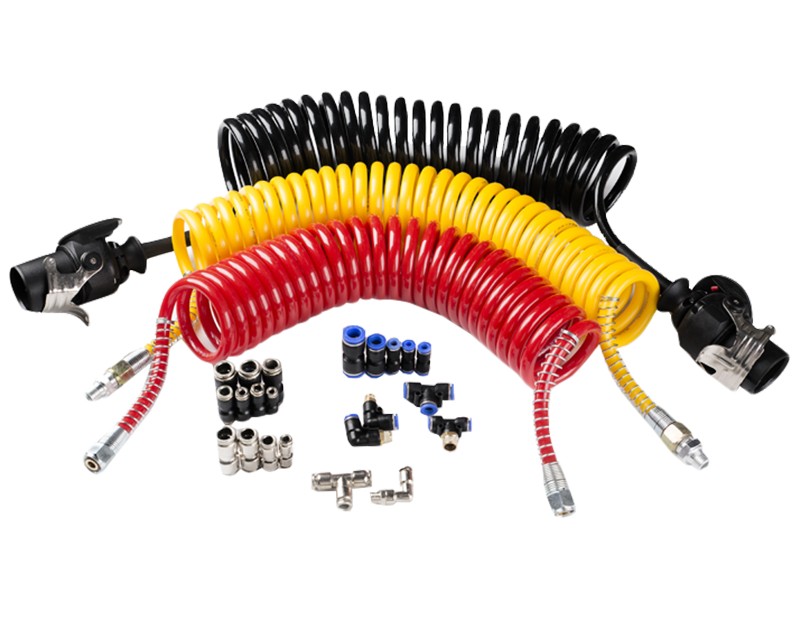

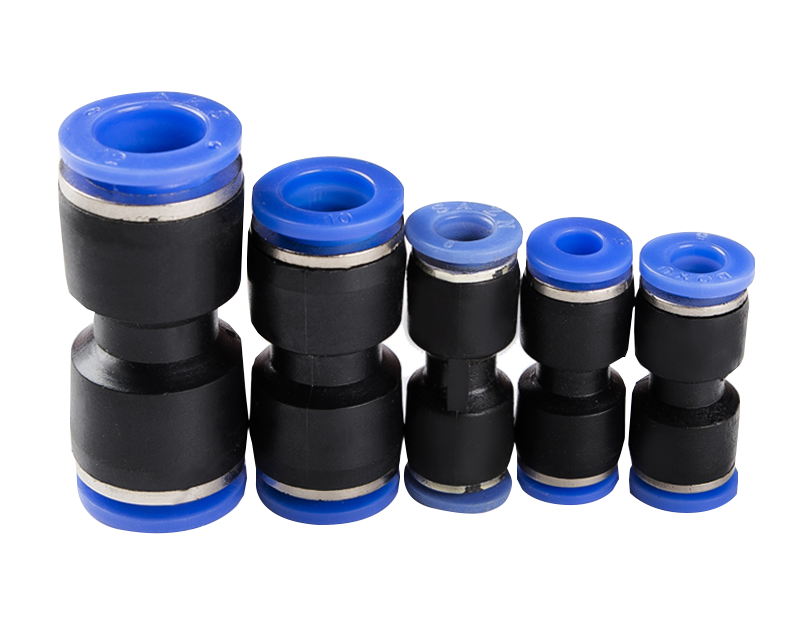

Quick disconnect fittings, also known as quick-release fittings, are types of mechanical fittings that allow for easy and rapid connection and disconnection of fluid lines. They are commonly used in a variety of industries, such as industrial manufacturing, automotive, and aerospace.

Quick disconnect fittings are designed to provide a quick and convenient way to connect and disconnect fluid lines without the use of tools. They consist of two parts, the plug and the socket, that connect together. The plug is inserted into the socket and is held in place by a locking mechanism, such as a collet or a ball and spring. To disconnect the fitting, the locking mechanism is released and the plug is removed from the socket.

Quick disconnect fittings are used in a wide range of applications, such as:

Industrial manufacturing: They are used to connect and disconnect fluid lines in a variety of industrial manufacturing processes, such as machine tools, robotics, and automation systems.

Automotive: They are used in the automotive industry to connect and disconnect fluid lines in systems such as fuel, oil, and cooling.

Aerospace: They are used in aerospace applications such as aircraft fuel systems, hydraulic systems and pneumatic systems.

Medical: They are used in medical equipment and devices such as oxygen supply systems and fluid delivery systems.

Home appliance: They are used in home appliances such as washing machine, dishwasher and refrigerator.

Quick disconnect fittings provide several advantages such as easy assembly and disassembly, minimal leakage and minimal maintenance. They are also designed for safety and reliability, and are available in a wide range of sizes and materials to suit different applications.

It's worth noting that it is important to ensure that the correct size, type and pressure rating of the quick disconnect fittings are used for the specific application

English

English Español

Español