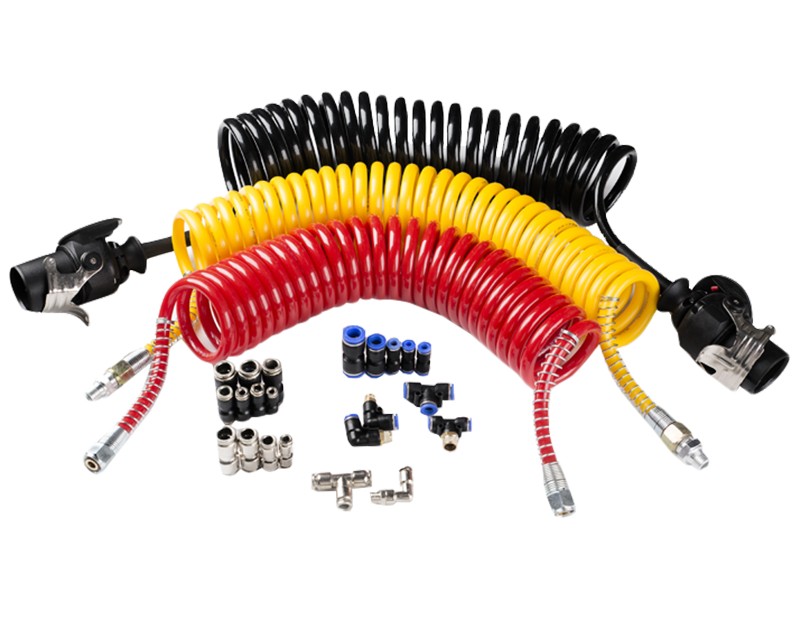

Pneumatic fittings serve as crucial components in various industrial and commercial settings, facilitating the connection and operation of pneumatic systems that utilize compressed air for power transmission. These fittings are designed with precision to ensure secure, leak-free connections between pneumatic components such as hoses, tubes, valves, cylinders, and actuators. However, the versatility of pneumatic fittings extends beyond air applications, as they can also be effectively utilized for fluid applications when selected and installed correctly.

One of the primary considerations when using pneumatic fittings for fluid applications is material compatibility. Pneumatic fittings are available in a range of materials, including brass, stainless steel, aluminum, and various types of plastics. Each material offers distinct advantages in terms of corrosion resistance, durability, and compatibility with different fluids. For instance, brass fittings are commonly used for both air and water applications due to their corrosion resistance and mechanical strength.

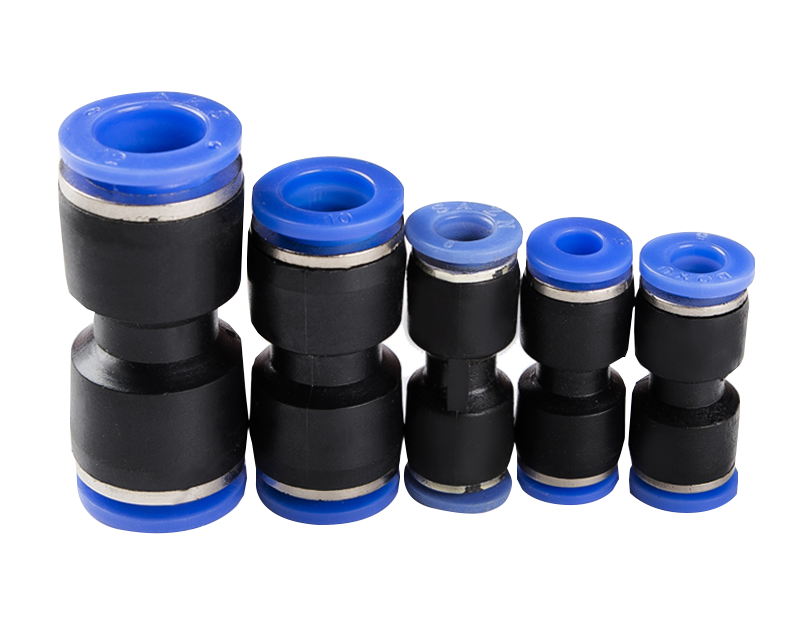

The sealing mechanism employed in pneumatic fittings is another critical factor to consider for fluid applications. Proper sealing is essential to prevent leaks and ensure the integrity of the fluid system. Different sealing methods, such as O-rings, compression fittings, and push-to-connect fittings, may be employed depending on the specific requirements of the application. It is crucial to select fittings with sealing mechanisms that are compatible with the properties of the fluid being conveyed to achieve reliable performance.

Furthermore, the pressure and temperature ratings of pneumatic fittings must align with the operating conditions of the fluid system. Fluid applications may involve higher pressures and temperatures compared to typical pneumatic systems, especially in hydraulic systems. Therefore, it is essential to choose fittings with appropriate pressure and temperature ratings to ensure safe and reliable operation under these conditions.

Additionally, the design and configuration of pneumatic fittings should be suitable for fluid applications. While some fittings are specifically engineered for air applications, others are designed to accommodate both air and fluid systems. Universal fittings, such as certain types of quick-connect fittings, offer versatility and flexibility for use in various applications. However, it is essential to verify the compatibility of the fitting design with the specific requirements of the fluid system.

Proper installation practices are critical when using pneumatic fittings for fluid applications. Care should be taken to follow manufacturer recommendations for installation procedures, torque specifications, and sealing methods to prevent leaks, damage, or improper operation. Regular maintenance and inspection of fittings are also essential to ensure continued performance and reliability over time.

English

English Español

Español