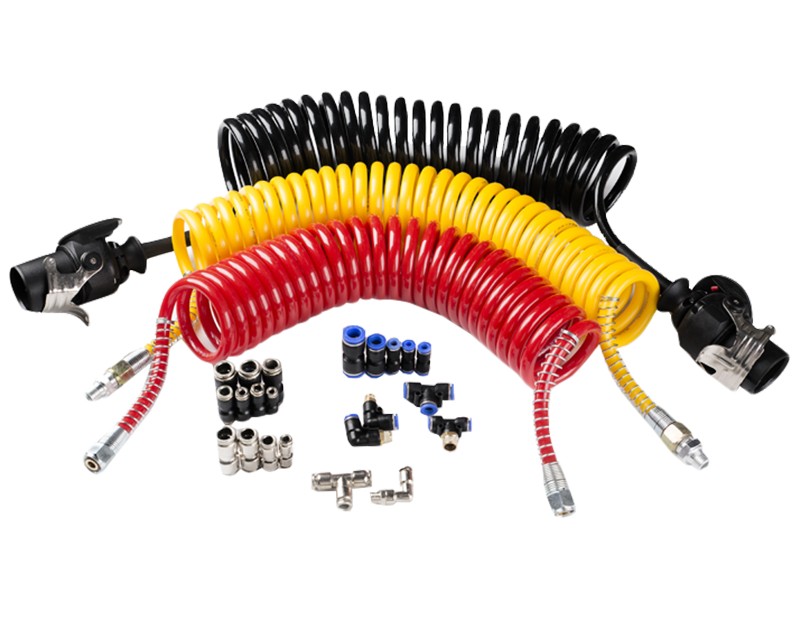

Quick disconnect fittings play a crucial role in pneumatic systems, offering a range of benefits that contribute to their efficiency, reliability, and ease of use. These fittings are designed to provide rapid connections and disconnections between pneumatic components, such as hoses, pipes, valves, and tools, without the need for tools or complex procedures. The use of quick disconnect fittings has become widespread across various industries due to their time-saving nature, ease of use, versatility, and other advantages.

One of the primary benefits of quick disconnect fittings is their ability to save time during assembly, maintenance, and repair tasks. In fast-paced industrial environments where efficiency is paramount, minimizing downtime is crucial. Quick disconnect fittings enable operators to quickly connect or disconnect pneumatic components, reducing the time required for setup, adjustment, or troubleshooting tasks. This time-saving feature translates into increased productivity and cost savings for businesses by minimizing idle time and maximizing equipment utilization.

Furthermore, quick disconnect fittings are designed for ease of use, making them accessible to operators of all skill levels. With their simple push-to-connect or twist-to-disconnect mechanisms, these fittings eliminate the need for specialized tools or training, allowing for rapid and intuitive operation. This user-friendly design enhances workplace efficiency and reduces the risk of errors or mistakes during pneumatic system assembly or maintenance tasks.

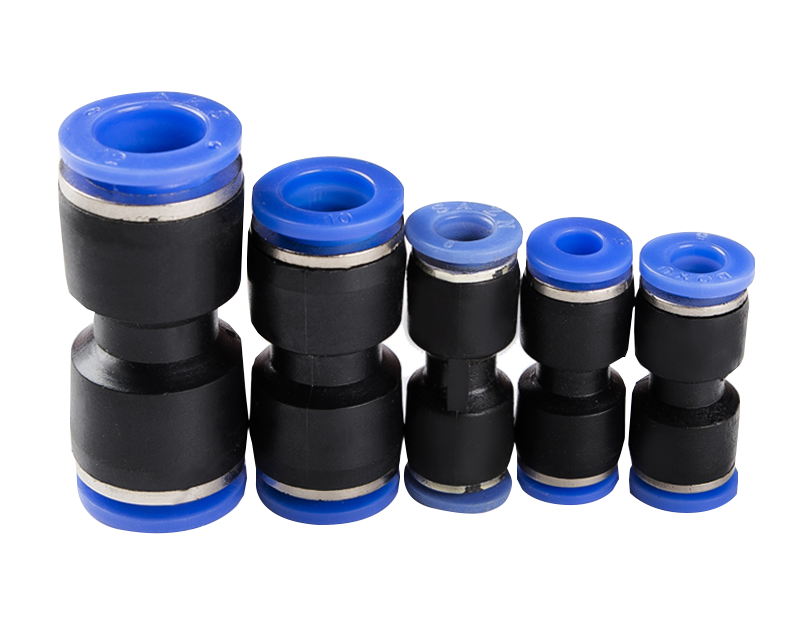

Versatility is another key advantage of quick disconnect fittings. These fittings are available in various configurations, sizes, and materials to accommodate different pneumatic system requirements and operating conditions. Whether it's a small-scale workshop or a large industrial facility, quick disconnect fittings can be tailored to suit the specific needs of the application. They can be used with a wide range of pneumatic components, including hoses, pipes, couplers, adapters, and tools, offering flexibility and versatility in system design and integration.

In addition to their versatility, quick disconnect fittings provide secure and reliable connections that minimize the risk of leakage in pneumatic systems. When properly installed and engaged, these fittings create a tight seal between mating components, preventing air leaks and maintaining system integrity. This reduces the likelihood of performance issues, equipment damage, or safety hazards associated with air leaks in pneumatic systems.

Another advantage of quick disconnect fittings is their modularity, which facilitates easy assembly, reconfiguration, or expansion of pneumatic systems. By allowing components to be quickly added, removed, or rearranged as needed, these fittings support agile and flexible system design. Operators can easily adapt pneumatic systems to changing operational requirements or production demands, enhancing overall efficiency and adaptability.

Quick disconnect fittings also contribute to safety in pneumatic systems by minimizing the risk of accidental disconnections or leaks. Their secure locking mechanisms and robust construction help prevent unintended separation of components, reducing the potential for injury or damage due to sudden air release or system failure. This enhances workplace safety and reduces the likelihood of costly accidents or incidents associated with pneumatic system failures.

Moreover, quick disconnect fittings are designed to be compatible with industry-standard pneumatic connections, ensuring seamless integration with existing equipment and components. They are available in various standard sizes and thread types, allowing for easy replacement or upgrade of pneumatic components without the need for extensive modifications or adaptations.

While quick disconnect fittings may have a higher upfront cost compared to traditional fittings, their long-term benefits outweigh the initial investment. Reduced labor costs, increased productivity, minimized downtime, enhanced safety, and improved system flexibility contribute to overall cost-effectiveness and return on investment for businesses using quick disconnect fittings in pneumatic systems.

English

English Español

Español