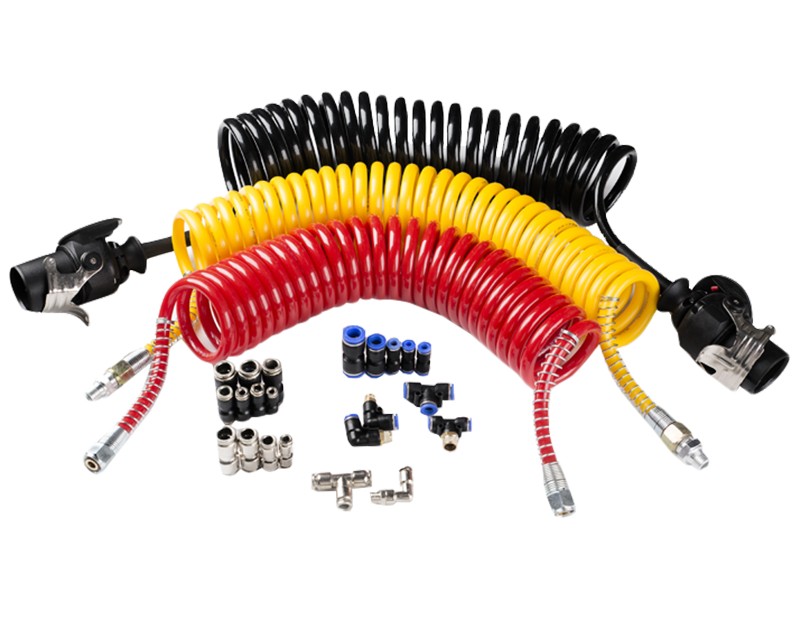

Properly storing and coiling air hoses is essential to maintain their integrity and functionality over time. Air hoses are vital components in pneumatic systems, providing the necessary connection between air compressors, pneumatic tools, and other equipment. Improper storage can lead to tangling, kinking, or damage to the hose, compromising its performance and potentially causing safety hazards during use.

When it comes to storing air hoses, the first step is to ensure that they are clean and free from any dirt, debris, or contaminants. Cleaning the hoses before storage helps prevent the accumulation of foreign particles that could damage the hose material or cause blockages in the airflow. Additionally, inspect the hoses for any signs of wear, cuts, abrasions, or kinks that may weaken the hose structure and affect its functionality. Addressing any issues before storage ensures that the hoses are in good condition and ready for future use.

After inspecting the hoses, it's important to disconnect them from the air source, whether it's an air compressor or pneumatic tool. This prevents the hoses from being under tension and reduces the risk of accidental release of compressed air during storage. Once disconnected, lay the hoses flat on the ground and straighten them out to remove any twists, kinks, or tangles. Straightening the hoses beforehand ensures that they coil smoothly and evenly without causing stress or damage to the hose material.

Choosing a suitable storage location for the air hoses is crucial to protect them from environmental factors that could degrade their performance. Ideally, store the hoses in a clean, dry, and well-ventilated area away from direct sunlight, extreme temperatures, moisture, or harsh chemicals. These conditions can weaken the hose material, degrade the hose fittings, or cause deterioration over time. Proper storage helps maintain the integrity of the hoses and prolongs their lifespan for continued use in pneumatic applications.

When coiling the air hoses, it's important to do so properly to prevent tangling and kinking. Start by holding one end of the hose in your hand and using the other hand to make loops of the desired size. Avoid pulling or stretching the hose excessively, as this can cause damage to the hose material or fittings. Instead, use a gentle and even motion to coil the hose without twisting or kinking it. To minimize tangling, consider using the over-under coiling technique, which involves alternating the direction of each loop to distribute stress evenly and maintain the natural curvature of the hose.

Once the hoses are fully coiled, secure them with a hose hanger, hook, strap, or hose reel to keep them neatly bundled and prevent them from coming undone during storage. This helps maintain the organization and integrity of the hoses, ensuring that they remain free from twists, kinks, or sharp bends that could cause damage. Additionally, consider using protective caps or plugs to cover the hose ends and prevent dirt, dust, or debris from entering the hose interior during storage.

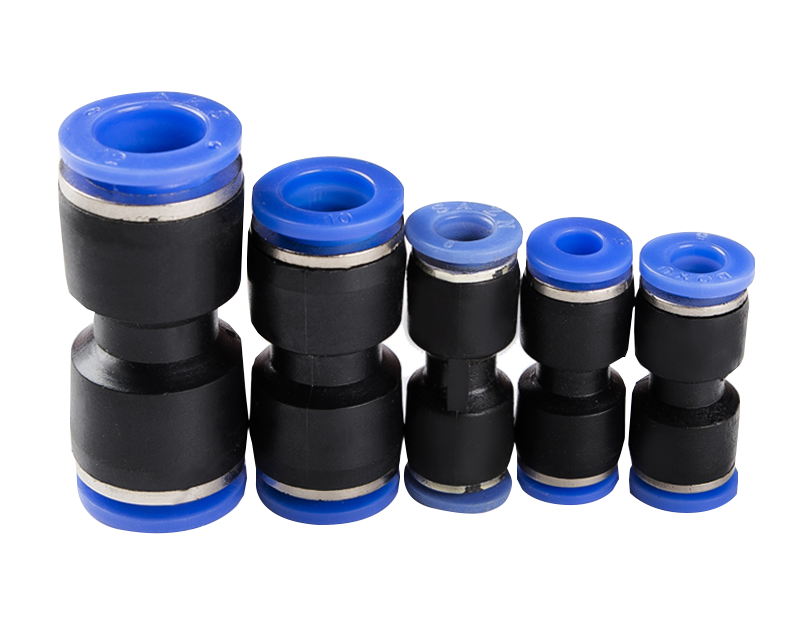

Regular inspection and maintenance of the stored air hoses are essential to identify and address any issues before they escalate into larger problems. Periodically check the hoses for signs of damage, wear, or deterioration, paying close attention to the hose fittings, connectors, and couplings. Replace or repair any damaged or worn components promptly to prevent leaks, malfunctions, or safety hazards during future use.

English

English Español

Español